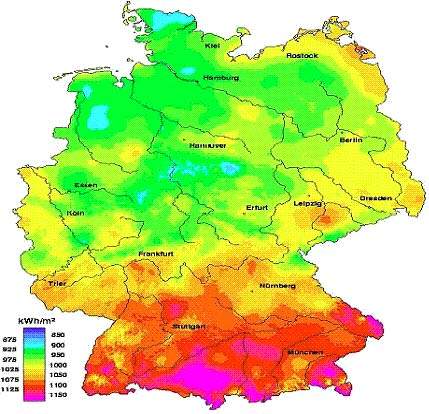

A partnership led by California-based PowerLight has constructed a 10MW photovoltaic facility in Bavaria, Germany. Billed as the world’s largest solar PV power plant, it cost €49.5m (US$59) and opened in June 2005.

The project uses 57,600 PV panels, and is made up of three separate systems: 6.3MW at Muehlhausen, 1.9MW at Guenching, and 1.9MW at Minihof. Solar trackers on the panels maximise energy production. Connection to the electrical grid was secured at each site by the regional German utility E.ON, with a 20-year power purchase guaranteed under the German Renewable Energy Law (EEG).

The project has already created hundreds of jobs and its sustainable design and construction preserves the natural beauty and environmental quality of the region. The project is equivalent to planting 20,300 acres (over 8,000 hectares), of trees and should reduce CO2 emissions by more than 100,000 tons over 30 years. The Bavaria Solarpark is scheduled to produce an excess of 215 million kWh of clean power over the next 20 years. It was awarded Power Engineering’s Best Renewable Project of 2005.

NEARLY 60,000 PANELS

Bavaria Solarpark covers around 26 hectares (62 acres) and uses nearly 60,000 PV panels. As the turnkey system provider, PowerLight (Berkeley, California) accepted responsibility for development, design, deployment, and operation. All three plants began producing electricity in 2004.

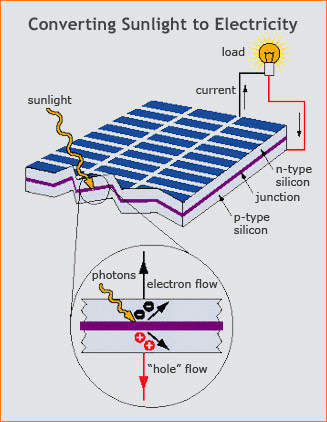

PV systems mainly use silicon cells to convert energy from sunlight into electricity. The DC electricity from PV modules is converted to AC by an electronic inverter. Systems can either be stand-alone or grid-connected. In grid-connected systems, the system produces power in parallel with the electrical utility, and feeds surplus power into the grid.

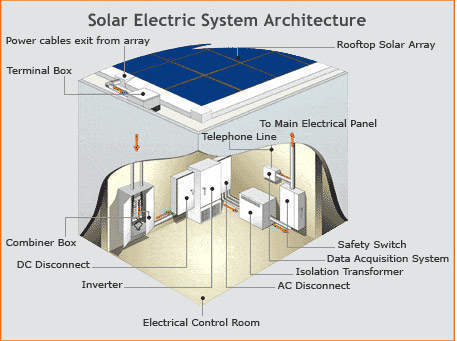

PowerLight’s Power Tracker follows the sun’s path, using one controller, motor, and drive per 10 to 20 rows. That gives between 18% and 35% more energy output than rigid systems in which the panels are installed at a fixed angle of inclination. The systems use a galvanised, corrosion-resistant steel frame, and withstand high winds. The construction scales from small to large multi-MW installations. A Data Acquisition System (DAS) provides daily system performance monitoring.

SIEMENS PROVIDING ELECTRICAL CONSTRUCTION

Siemens Power Transmission and Distribution Group (PTD, Erlangen) is providing all electrical construction and components. In an order worth €4m, Siemens will supply 10 transformers for the 20kV voltage level, five 8DJ20 gas-insulated switchgear assemblies and 27 Sinvert 340 kVA solar inverters. The plant also will feature a control system based on Simatic PCS7, enabling all data to be recorded and evaluated using WinCC (Windows Control Center for Windows 2000 and XP). Siemens will connect the plant to the public power supply network and maintain the inverters.

The project was financed by Deutsche Structured Finance (DSF) of Frankfurt. Leading German civil engineering firms, Max Bögl Group and Klebl are responsible for the civil and mechanical project construction. K&S (Regensburg, Germany) company helped arrange project rights.

GERMAN INCENTIVES ENCOURAGE PVs

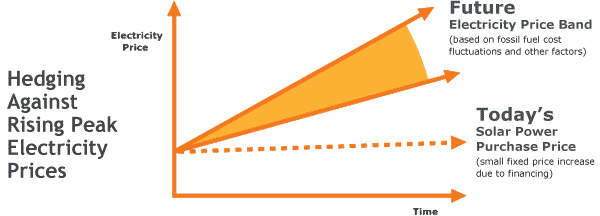

Founded in 1991, PowerLight has built and now operates many of the largest solar electric systems in North America and Europe. The company has mainly designed and constructed projects in California where state incentives have helped the solar industry. The incentives in California are based on the installed kW size of a project, while Germany’s method provides a rebate price per Watt delivered by a particular project to the local electric grid.

Germany’s incentives are considerably better than California’s, and have been cited for attracting a large proportion of the worldwide solar PV supply. This legislation, expanded to include ground-mounted systems such as the Bavaria Solarpark, is expected to drive further growth of the German PV market. The assistance ensures 20-year solar electricity purchase at around $0.50/kWh for 20 years.