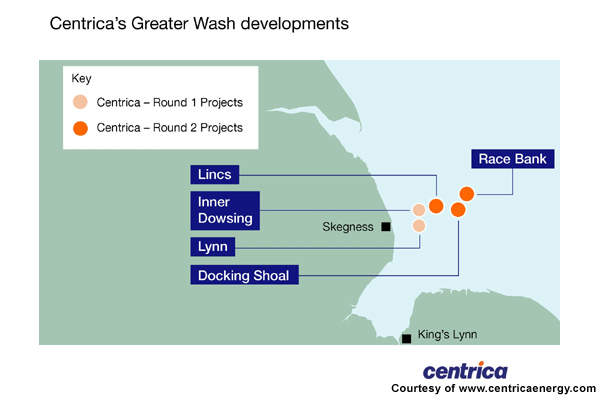

The Centrica Lincs offshore wind farm is one of the five renewable projects developed by Centrica Renewable Energy (Centrica) in the Greater Wash, UK.

The development is located approximately 8km from the Skegness coast, immediately adjacent to the Lynn and Inner Dowsing wind farms, two of Centrica’s renewable projects that became operational in March 2009. The Lincs project began construction in 2010 and was commissioned in September 2013. The project received the agreement for lease in 2003, a consent application grant in late 2008 and the final investment approval in the final quarter of 2009.

The £725m project annually generates 270MW of electricity. The permitted annual capacity of the project is 250MW. The remaining 20MW was constructed in the Lynn and Inner Dowsing wind farm area and connected to the transmission of Linc. The wind farm powers the annual electricity requirements of approximately 200,000 households, with zero emissions.

The project is jointly owned by Centrica, Siemens Project Ventures and DONG Energy. Siemens Project Ventures and DONG Energy acquired a 50% stake in the project from Centrica, by forming a joint venture in December 2009. Centrica owns the remaining 50% stake.

Centrica Lincs turbines and plant details

The 35km² north-south oriented wind farm is composed of 75 three-blade turbines with horizontal-axis installed in a water depth from 10m to 15m in the North Sea. The Siemens turbines have a capacity of 3.6MW each, and are equipped with 120m-diameter rotor and 58.5m-long rotor blades.

The maximum height to the tip of the blade is 170m and the turbines are spaced at a distance of 500m. The hub height is 100m. The nacelle and hub of the turbines were installed atop a cylindrical steel tower that is further supported by a foundation attached to seabed.

Construction

Onshore construction began in 2010, with offshore work following in 2011. The initial enabling works on the Walpole substation site were completed, improving the traffic safety while entering and leaving the site. Between April 2010 and June 2011, two high-voltage cables were installed from the landfall to the new onshore substation site.

The 145kV cables are 50km each in length and were supplied by Nexans Norway AS. The cables were drawn through cable ducts buried at distances of 1km along the entire cable route. Methods for duct installation included direct buried, open cut or horizontal directional drilling (HDD).

A substation to connect the wind farm with the national grid network was erected in the third quarter of 2011. Piling was carried out using continuous flight auger (CFA), a quieter method that also creates less vibration.

Works also included construction of new access roadways, a road junction and civil works besides installation of steelwork, mechanical and electrical equipment.

Landfall works conducted in 2010 included the installation of three 1,000m-long steel ducts beneath the sea wall and salt marsh. Two 16in-diameter ducts were used separately for two export cables. The 6in-diameter third duct was employed for the mud return line during drilling operations.

During the work period, a 60m x 20m barge was brought and moored approximately 1km from the sea wall. An on-board drilling rig conducted drilling under the salt marsh found at pre-defined locations in the first field behind the sea wall. Each hole was reamed out before a fabricated steel duct was drawn through the hole with the rig.

Contractors

The main contractor for onshore works of the project is Siemens Transmission and Distribution. The contractual scope included design and building of the grid connection and laying of the cables onshore. The contract for the supply of turbines was awarded to Siemens in March 2009. Siemens Project Ventures was awarded the contract to design the offshore and onshore substations.

Fugro GeoConsulting was chosen as the geotechnical surveyor. SGS-International Certification Services was the risk management consultancy for the project.

Grid Network

The wind power plant is connected to a new substation via two underground 132kV cables. Approximately 40km-long, the cables are partially buried within the seabed at a depth of 1m and 3m, and partially onshore. Before supplying the national electricity network, power is increased from 132kV to 400kV at the substation located adjacent to the current substation at Walpole.

Power market in the UK

The UK’s total electricity supply in 2008 was 400,671Gwh. Approximately 46% of this was contributed by gas-powered plants. Coal, nuclear, renewable, imports and oil accounted for 31%, 13%, 6%, 3% and 1% respectively. The installed electricity generation capacity of coal, gas, nuclear and other power stations stood at 83.5GW, with less than 0.5GW coming from wind.

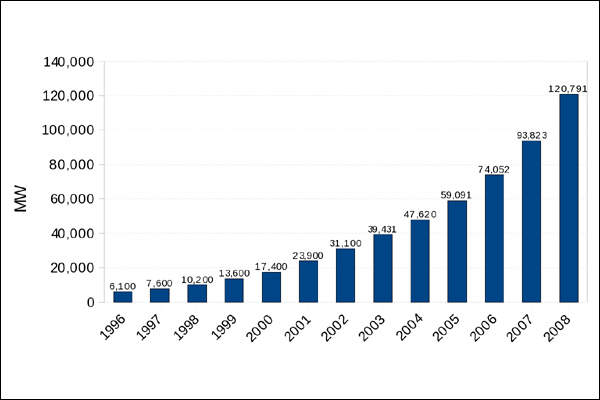

In 2009, however, nearly 1,077MW of new wind capacity was installed in the UK, accounting for 10% of the total capacity installed in the whole of the European Union. More than 1,190MW of new wind capacity was installed in 2010. By 2020, the target is to install approximately 33GW of wind turbines.

With large expansion of offshore wind-power plants taking place in the North Sea, the Irish Sea and around the coast of Scotland, nearly half of the UK’s current electricity consumption is expected to be met by wind farms by 2020.