Exelon Generation is developing a new 1,000MW low-carbon, combined-cycle gas turbine (CCGT) unit at its existing 498MW natural-gas powered Colorado Bend generating station in Wharton County, Texas, US. It is one of two new CCGTs being developed by Exelon, the other one being the 1,000MW unit at the existing Wolf Hollow Generating Station in Granbury, Texas.

The ground breaking ceremony for the CCGT unit at Colorado Bend was conducted on 9 July 2015 and commercial operations began in 2017. The new plant is expected to have a maximum electric power output of 1,157MW.

Colorado Bend generating station expansion

The 420MW facility is being replaced by a more environmentally friendly and energy-efficient CCGT plant.

The existing natural gas-fired Colorado Bend generating station started operations in 2007 with a capacity of 225MW and was expanded to 550MW in 2008. It consists of a full steam turbine bypass, which allows the combustion turbine generator and heat recovery steam generator to come up to full load independent of the steam turbine generator.

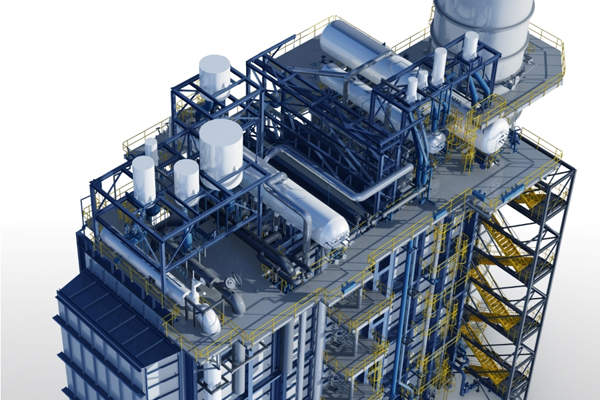

The latest expansion will include the installation of two new General Electric (GE) H-class 7HA.02 gas turbines and two heat recovery steam generators (HRSGs). The GE technology is expected to make the unit one of the cleanest and most efficient CCGTs in the US.

The combustion gas turbines will be equipped with dry low-NOx (DLN) combustors and have a maximum base-load electric power output of 337MW.

The HRSGs will recover exhaust heat from the gas turbines to produce steam that maximises the power generation capacity and efficiency. The generators will be installed with unique Optimised for Cycling and Constructability (OCC) technology, which will provide unparalleled flexibility for reliable high-cycling duty.

Integrated catalytic oxidation (CO) and selective catalytic reduction (SCR) technologies within the generators will improve the plant performance, while also reducing emissions.

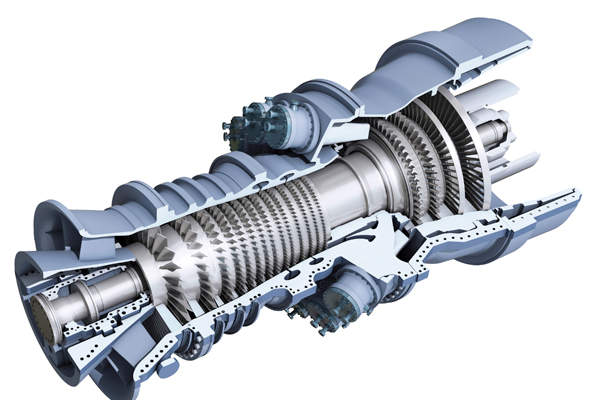

Turbine technology used in the CCGT unit

The 7HA.02 gas turbine model represents one of the biggest 60Hz gas turbines in the industry. It comes with a four-stage, air-cooled, hot gas path with advanced cooling and sealing technologies for improved efficiency and allows more starts per inspection interval.

The turbine also consists of a 12-chamber DLN 2.6+ combustion system with a design life of more than one million hours and 18,000 starts. The turbine also consists of a 12-chamber DLN 2.6+ combustion system, which helps in superior turndown and wide fuel capability, while maintaining low emissions.

Power generation from Colorado Bend

Each combustion turbine will consist of a compressor, combustor, expansion turbine and generator. The compressor pressurises the inlet combustion air to the combustor, where natural gas will be mixed with combustion air and burned.

The hot exhaust gases from each combustion turbine will be directed through their respective HRSG, consisting of a set of natural gas-fired duct burners (DBs). The DBs will have a maximum heat input capacity of approximately 770MMBtu/hr higher heating value (HHV).

Steam from the HRSGs will be delivered to a single steam turbine generator (STG) with a gross electric power output of approximately 501MW at 69.7°F. The two combustion turbines and one steam turbine will be connected to electric generators to produce electricity that will be sold to the Electric Reliability Council of Texas (ERCOT) power grid.

Infrastructure facilities

Apart from using the existing infrastructure at Colorado Bend, the new unit will include the construction of a nominally-rated, 2,937-bhp diesel-fired emergency generator (EPN EG3) to provide electricity to the facility in case of power failure. A 250bhp diesel-fired water pump (EPN FWP2) will provide water supply in the event of a fire.

Contractors involved with the expansion

Alstom was awarded a contract worth more than $100m to supply two heat recovery steam generators (HRSGs) for the new CCGT plant at the Colorado Bend generating station.

Zachry was awarded the engineering, procurement and construction (EPC) services contract for the new CCGT unit.

Black & Veatch is the owner’s engineer for the expansion project. Jackson Walker represented Exelon in the completion of the EPC contract and procurement of GE combustion turbines, Alstom HRSGs and other major equipment.