Taiwan’s largest natural gas-fired combined-cycle power plant, Datan (also known as Tatan or Dah-Tarn power plant), is located in Taoyuan city, approximately 50km west of Taipei city.

It is owned and operated by Taiwan Power Company, a state-run electric utility provider.

The power plant became operational in 2005 and currently has seven units with a combined power generating capacity of 4,986MW. It is being expanded with three high-efficiency gas-fired combined-cycle units.

Datan power plant location

Datan power plant lies at the Datan coastal industrial park of the Guanyin district in Taoyuan city, in a 116.02ha site.

A vacant plot located south of the existing power plant with an area of approximately 19.8ha will be used for the expansion.

Datan power plant refurbishment and expansion

The M501F combined-cycle gas turbines of the first six units of the natural gas-fired Datan power plant were upgraded with new low-NOx FMk8 model combustors and improved turbine blades in 2018.

MHPS-TOMONI, a digital solution service, was used to support the upgrade. The refurbishment was completed in 2019.

Unit seven was installed with two simple-cycle gas turbines of 300MW each in 2018. It is being converted into a combined-cycle system by adding steam turbine equipment.

The conversion will improve the unit’s efficiency and increase its power generation capacity from the current 600MW to 900MW.

Taipower awarded the ¥130bn ($1.2bn) engineering, procurement and construction (EPC) contract for the units eight and nine to the GE-Marubeni consortium in February 2019 and ordered four 7HA gas turbines from GE for the units.

Turbine details

The Datan power plant’s three new combined-cycle units for units seven, eight and nine will have a thermal efficiency of 60.7% and net combustion of 5,930kJ/kWh. The operating speed of the turbine will be 3,600rpm.

The units will use horizontal gas flow type heat recovery steam generator, hydrogen-cooled / three-phase synchronous machines generator and outdoor type oil-immersed / three-phase / 60Hz transformer. Selective catalytic reduction (SCR) system is used in the plant for environmental protection.

Construction

Piling and foundation work is underway at the power block and balance-of-plant area. The supplies will reach the power plant through a new import terminal at Taichung. The 36in-diameter Taichung-Tunghsiao-Tatan offshore pipeline connects the terminal to the power plant.

The ground-breaking of the second phase of unit seven was performed in July 2020 with commercial operation expected to start in June 2024. Units eight and nine will become operational in 2022 and 2023 respectively.

A 161kV underground cable is being laid from Datan to Linkou for the power transmission from the plant.

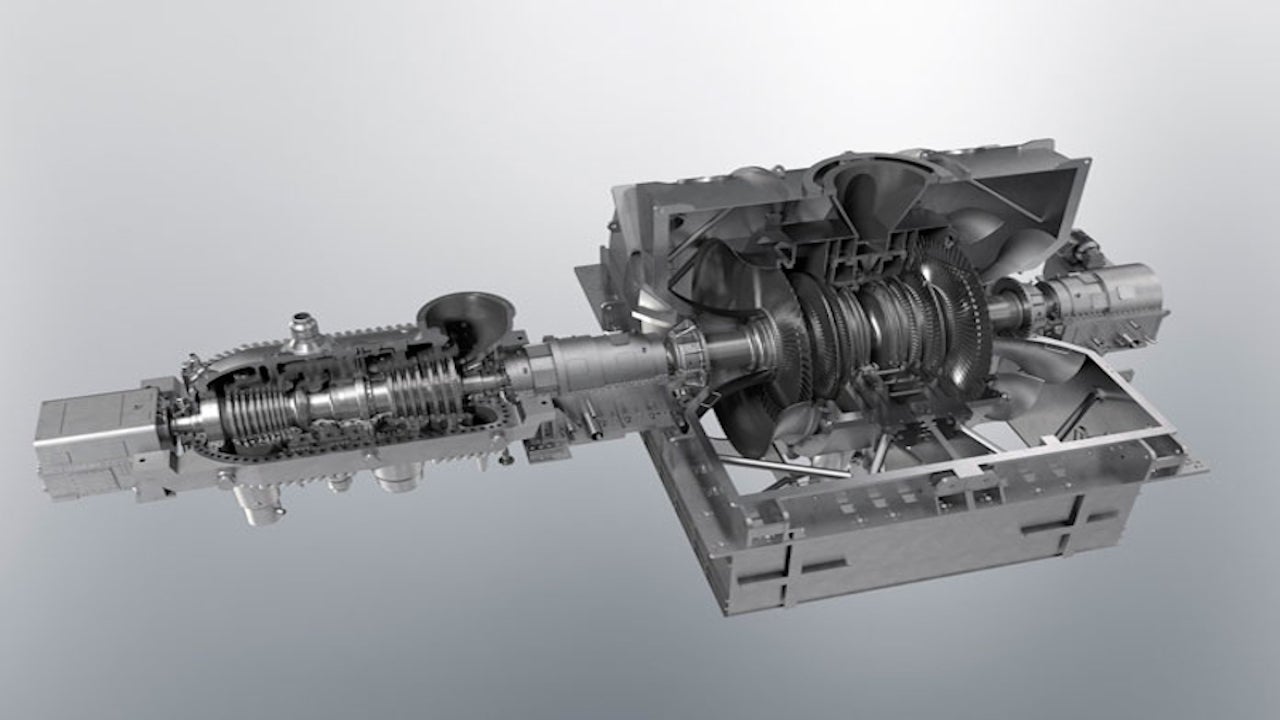

Features of 7HA gas turbine

GE’s 7HA is a heavy-duty high-efficiency, air-cooled gas turbine with combined-cycle output between 438MW and 640MW in 1×1 configuration and combined-cycle output from 880MW to 1,282MW in 2×1 configuration.

The combined-cycle efficiency of the gas turbine is more than 64%. Its simplified dual-fuel system reduces the usage of water and eliminates recirculation.

Contractors involved

Mitsubishi Hitachi Power Systems (MHPS) received an order to provide steam turbine power-generating equipment for the conversion of the simple-cycle gas turbines of unit seven to a gas turbine combined-cycle (GTCC) system in April 2020.

The steam turbine and electric power generator for the conversion will be manufactured at MHPS’ Hitachi Works plant in the Japanese prefecture of Ibaraki.

A consortium of General Electric (GE) International and Marubeni is the primary contractor for the addition of units eight and nine.

GE Group is supplying the major equipment, including gas and steam turbines, generators and waste heat recovery boilers, while Marubeni is responsible for providing associated machinery and performing engineering and installation work.

Nippon Export and Investment Insurance (NEXI) will provide export credit insurance for the construction of the units.