The 1,600MW Shuweihat S3 combined cycle power plant is located at Ruwais in the emirate of Abu Dhabi, United Arab Emirates (UAE). Shuweihat Asia Power Company (SAPCO) developed the plant, in which Abu Dhabi Water & Electricity Authority (ADWEA) owns 60%, while the remaining 40% is owned by the Sumitomo Corporation of Japan and the Korea Electric Power Corporation (KEPCO).

Construction of the gas-fired power plantstarted in 2011 and the first gas turbine was ignited in July 2013. The project started commercial operations in August 2014.

The AED 5.5bn ($1.5bn) project is the third Shuweihat plant following the 1,500MW Shuweihat S1 and Shuweihat S2 combined cycle power plants, which have been operational since 2004 and 2011, respectively. The 1,600MW Shuweihat S3 power facility is operated by the Shuweihat Asia O&M Company (SAOM).

Shuweihat S3 power plant details

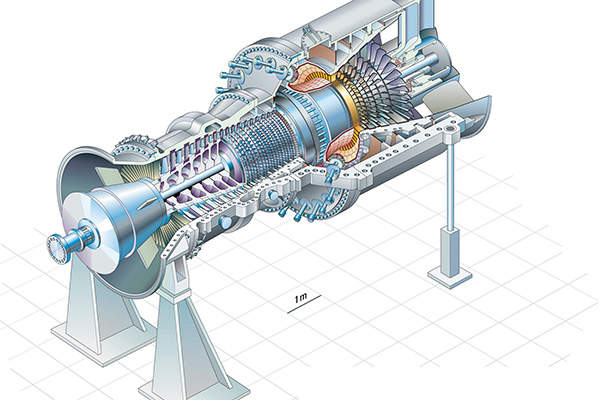

The Shuweihat S3 power plant comprises two combined cycle power blocks consisting of two Siemens SGT5-4000F gas turbines, one SST5-4000 steam turbine and two dual-pressure heat recovery steam generators (HRSG), each with bypass stack.

SGT5-4000F is a four-stage axial-flow gas turbine including a multi-stage axial-flow compressor with variable-pitch inlet guide vanes, as well as an annular combustion chamber equipped with 24 hybrid burners for gas and oil firing.

Ambient air is pumped into the compressor through an inlet air filter and the compressed air is fed to the combustion chamber from where the resultant hot, compressed combustion gas is transferred to the turbine. It then expands to drive the turbine and generator. The energy output from the generator is transferred via a transformer and bus bars to the power grid.

The steam turbine used at the combined cycle power plant is a dual-casing condensing turbine comprising a high pressure (HP) turbine section and a double-flow low pressure (LP) turbine section.

Air-cooled turbine generators are used for the gas turbines and hydrogen-cooled generators are used for the steam turbines. Horizontal dual-pressure HRSGs used at the plant are equipped with a natural circulation evaporator system.

Exhaust steam from the turbine is condensed in two-pass condensers and the steam in the condenser shell is cooled with seawater.

Power transmission

The power generated at the plant is transferred to the power grid via a gas-insulated 400kV 8DQ1 switchgear unit. The electricity is sold to Abu Dhabi Water and Electricity Company under a 25-year power purchase agreement.

Shuweihat S3 combined cycle power plant financing

Japan Bank for International Cooperation (JBIC), the Export-Import Bank of Korea (KEXIM) and a group of financial institutions, including BNP Paribas, Mizuho Corporate Bank, Bank of Tokyo Mitsubishi-UFJ, HSBC, National Bank of Abu Dhabi, Samba Financial Group, and SMBC and the Mandated Lead Arrangers, provided long-term loan facilities amounting to $1.1bn for the Shuweihat S3 project. The financing also included $280m of equity bridge facilities.

The project achieved financial closure in 2011 and Ashurst acted as the lenders’ advisor.

Contractors involved

The engineering, procurement and construction (EPC) contract for the power plant was awarded to a consortium consisting of Daewoo Engineering & Construction (E&C) and Siemens, in March 2011.

Siemens, the lead EPC contractor, supplied the turbines and generators along with the complete instrumentation and control (I&C) system and a gas-insulated 400kV 8DQ1 switchgear unit.

Daewoo E&C was responsible for site construction and civil works and also provided the HRSGs and the balance of plant (BOP). Daewoo engaged Inco to install the HRSGs and piping, construct storage tanks and to perform the BOP works.

Hatch provided technical advice to Sumitomo and KEPCO during the bid preparation and contract negotiation phases.