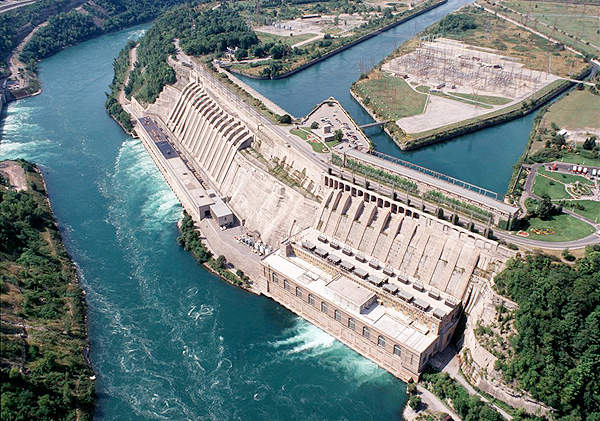

The Sir Adam Beck (SAB) hydroelectric power generating complex is located at Queenston Heights, Ontario, Canada. It consists of two power generating stations – Sir Adam Beck I and Sir Adam Beck II. The complex is owned and operated by Ontario Power Generation (OPG), one of the largest electricity producers in North America. OPG supplies about 70% of Ontario’s annual power requirements.

OPG is constructing a major tunnel to divert additional water downstream to the SAB II power station from upper Niagara Falls, with the help of gravity. It will increase the output capacity by 14%. The C$1.6bn project is being funded by Ontario Electricity Financial Corporation (OEFC) and the Province of Ontario.

The project will help in meeting the energy requirements of Ontario through clean and renewable hydropower. It will allow power generation for more than 100 years with minimal maintenance.

Ontario’s Sir Adam Beck (SAB) facility history

The 59km long Niagara River runs from a north-south direction from Lake Erie to Lake Ontario at an average rate of 6,000m³/s. Water for power generation is shared equally between OPG in Canada and the New York Power Authority in the US, under the 1950 Niagara Treaty and subsequent notes.

SAB I, known as the Queenston Chippawa power station until 1950, was commissioned in 1922. It has ten generating stations and an output capacity of 498MW. SAB II became operational in 1954.

Details for Canada’s SAB hydroelectric power complex

Water for SAB I is supplied through a 20km long canal from the upper Niagara River.

SAB II consists of 16 generating stations producing 1,499MW. Water for this station comes from two nine kilometre long twin diversion tunnels from the Niagara Falls, built in the 1950s. A water reservoir was also constructed in 1958 to generate additional electricity.

The complex receives about 1,800m³/s of water for a total output of 2,080MW. Currently, the Canadian water share for power generation exceeds the SAB generating capacity due to the retirement of the Rankine, Toronto Power and Ontario Power generating stations.

A major upgrade of SAB II during 1996-2005 increased the capacity of the station by 194MW and paved the way for the Niagara Tunnel Project.

Hydroelectric power generation process at the Queenston Heights plant

Clean and renewable hydroelectricity is generated by diverting water from the high elevation of the falls through tunnels to the power generating stations. The water is dropped on the rotating blades of turbines from an elevation of about 100m through penstock.

These spinning blades are connected to electromagnets of the generators through shafts. Spinning electromagnets create electricity in a stationary wire coil. Generated electricity is fed to transformers to boost the voltage and then transmitted to longer distances over power cables.

Niagara Tunnel Project and largest hard rock TBM ever, Big Becky

The 10.2km long, 14.4m diameter hydroelectric tunnel is the third to divert water to SAB generating station II. It will increase the water flow to the station at a rate of 500m³/s and allow additional 1.6 billion kWh electricity generation per annum.

This is sufficient to power 160,000 homes. The tunnel runs parallel to the existing tunnels below the city through Stanley Avenue at depths of 90m-140m. It will increase the capacity of SAB II by 150MW.

The project utilised The Robbins Company’s tunnel boring machine (TBM) built through onsite first time assembly (OFTA). The 150m long, 14.4m high and 4,400t machine, named Big Becky, is the largest hard rock TBM ever built. The cutterhead used 20in cutters and had a thrust of 18,462kN and torque of 18,670,000N-m.

Tunnel construction linked to the Sir Adam Beck (SAB) generating complex

Construction at the outlet section of the tunnel began in September 2005 and then at intake in January 2006. Tunnel boring was carried out from 2006 to May 2011. It will be finished with 24in thick unreinforced cast concrete lining and polyolefin waterproofing membrane.

The project was previously scheduled for completion by late 2009. It was, however, delayed until December 2013 due to unstable rock conditions resulting in slower mining. Tunnel alignment was also slightly modified to limit the overbreak in the Queenston shale formation, in December 2008. It resulted in 0.2km lesser tunnel length (against the planned 10.4km).

In August 2005, OPG selected Strabag as the design-build contractor for the Niagara Tunnel Project. The company will also be responsible for remedial works at the retired Toronto Power Station and its intake gate house. The total value of the contract is C$1bn.

ILF Consulting Engineers and Morrison Hershfield are the tunnel design consultants. Castonguay Blasting Company, Dufferin Construction, Bermingham Construction Company and McNally International are the subcontractors for geology study, intake, outlet structures and emergency closure gate.

The Robbins Main Beam TBM, along with a 105m backup system and conveyor belt, cleared 1.7 million cubic metres of muck during the Niagara Tunnel Project mining. DSI Austria and DSI Underground Systems supplied tunnelling systems for the project. Hatch Acres and Hatch Mott MacDonald are the owner’s representatives.