MHI is building a 400MW gas turbine combined-cycle (GTCC) power plant for Endesa at San Isidro II, Chile. The natural-gas/oil-fired plant is estimated to cost $190m. It is being built near Quillota city, about 130km northwest of the capital Santiago. The turnkey plant will form the core of the San Isidro II facility, which aims to prevent power shortages around the capital.

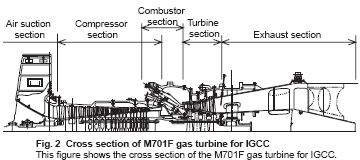

San Isidro II will have an M701F gas turbine, steam turbine, heat recovery steam generator (HRSG) and two generators. MHI will design and make the gas and steam turbines and HRSG, while Mitsubishi Electric Corporation will build the generators. Mitsubishi has signed a 12-year maintenance contract for the project.

In the first stage, from March 2007, San Isidro II will generate electricity by gas turbine only. Later, a steam turbine and HRSG will be added for GTCC power generation, scheduled to go on stream in February 2008. It will use gas from a proposed LNG (Liquefied Natural Gas) regasification terminal that will be built on the coast.

UP-RATED MITSUBISHI F-SERIES

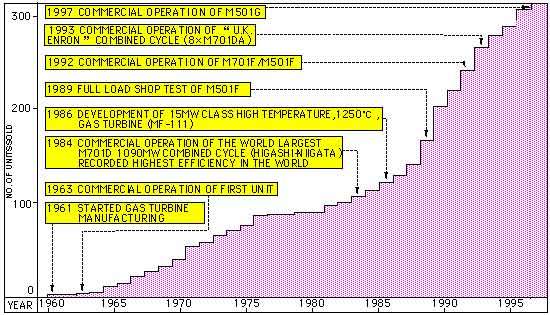

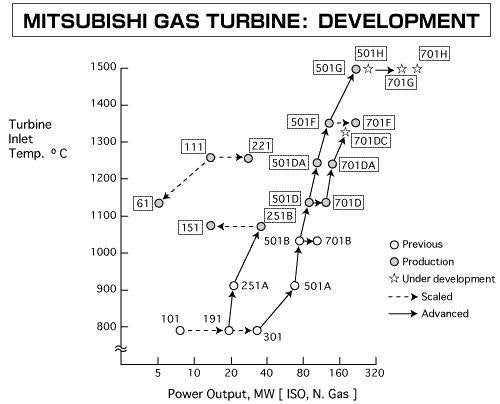

The F-series was developed in the late 1980s, based on research at MHI Takasago R&D centre. The 60Hz M501F was followed by the 50Hz M701F. Total accumulated operating hours for the family already exceeds 1.2 million.

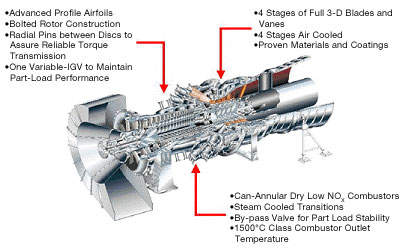

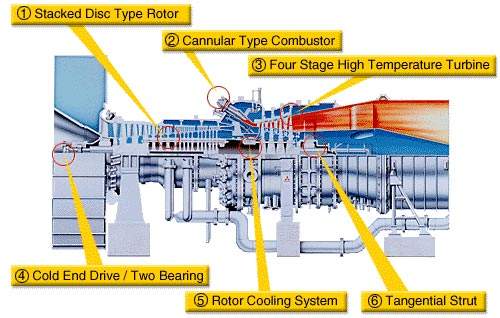

GTCC turbines generate electricity in two stages, using high-temperature exhaust gas from the gas turbine. That gives high thermal efficiencies. Mitsubishi’s pre-mix DLN combustor has 15ppm NOx emissions. Active on-line combustor sensors protect against combustion flame instabilities. Current F-series gas turbines are up-rated versions, retaining strengths at increased gas temperatures. The turbine inlet gas temperature is now 1350°C.

The F-Series turbines have a two-bearing single-shaft construction with cold-end power drive and axial exhaust. A double shell casing prevents rubbing between stationary and rotating parts. High strength durable and repairable hot gas path materials replace more expensive single crystal parts.

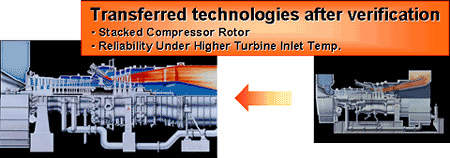

Other improvements have come from the company’s G-series. They include thermal barrier coating, and advanced turbine blade and vane material. The up-rated F-series has the same number of compressor and turbine stages, combustors, rotor configuration and materials. Bearing span, compressor and turbine aerodynamic design are also retained.

Huge torques are transferred through the compressor shaft of a gas turbine to the generator. MHI’s compressor shaft has radial pins at the disc contact surface to ensure torque transfer, preventing disc slippage. The rotor cooling air is extracted from compressor discharge and cooled in an external cooler. That allows MHI to use 3-1/2 Ni alloy steel material for long rotor life. Dissipated heat at the cooler is effectively recovered as fuel heating to obtain better thermal efficiency.

RECOVERY IN CHILEAN CONSUMER SPENDING

Consumer spending in Chile has been recovering since mid 2002. The country has also been receiving higher prices for copper in the international market, representing 40% of Chile’s exports. As a result, real GDP growth was around 6% in 2004 and 2005.

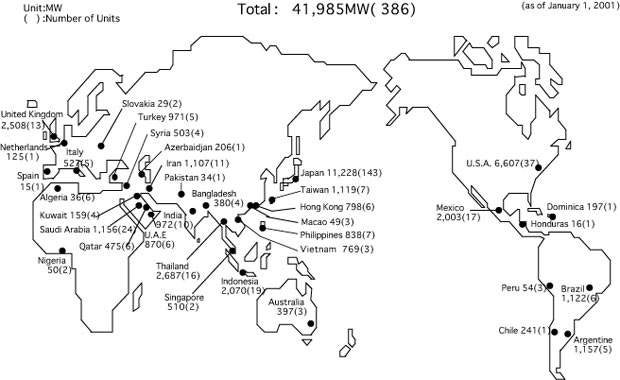

This high economic growth has increased electricity demand, and regions like Santiago now risk electricity shortages. The new plant adds to the San Isidro I GTCC plant built by MHI in 1996. This started operation in October 1998. The environmental impact study (EIS) for San Isidro II received final approval in August 2004.

ENDESA NOW OWNS 100% OF ISIDRO

Endesa Generación was set up in September 1999 to oversee Endesa’s generation and mining assets in Spain. In June 2000, the company integrated mainland subsidiaries that it already owned (Sevillana II, Fecsa-Enher II, Erz II and Viesgo II). Then, in 2004, the company also took over Endesa Cogeneración y Renovables (ECYR), which operates the renewable and co-generation power plants. Around 44% of Endesa’s assets in Latin America are in Chile.

Endesa is also the controlling shareholder of Enersis, Latin America’s largest private electricity group, with a 60.62% stake. It therefore has a controlling 59.98% interest in Endesa Chile, Chile’s largest power generator, alongside stakes in other Chilean generators. Both directly and through subsidiaries, Enersis has total installed capacity of 4,300MW. After having acquired Globeleq for $21m (slightly over €17m), Endesa Chile now owns 100% of San Isidro.