The CPV Towantic Energy Centre is an 805MW combined-cycle power plant (CCPP) constructed on a 26-acre site within the Woodruff Hill Industrial Park in Oxford, Connecticut, US.

The project was developed by Competitive Power Ventures (CPV) in collaboration with GE Energy Financial Services. It was originally approved as a 512MW power plant in 1999 by the Connecticut Siting Council, but could not materialise due to financial issues faced by the former developer Towantic Energy, a subsidiary of Arena Capitol.

CPV acquired the project in 2012 and partnered with GE Energy Financial Services to advance the project, making further improvements to the original design by enhancing the nameplate capacity and incorporating more efficient technologies.

The redeveloped project was approved by the Connecticut Siting Council in May 2015, the final investment decision for the project was made in March 2016 and commercial operations started in June 2018.

Financing the 805MW CCPP

A debt financing of $753m was provided for the project by a total of 16 lenders, with MUFG Union Bank, Credit Agricole Corporate and Investment Bank, and CIT Bank acting as the lead arrangers.

CPV Towantic Energy Center make-up and design

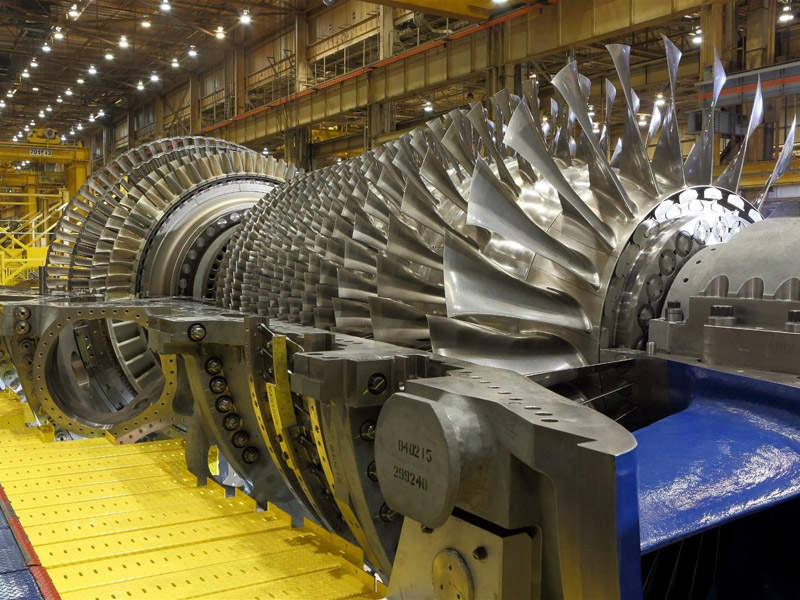

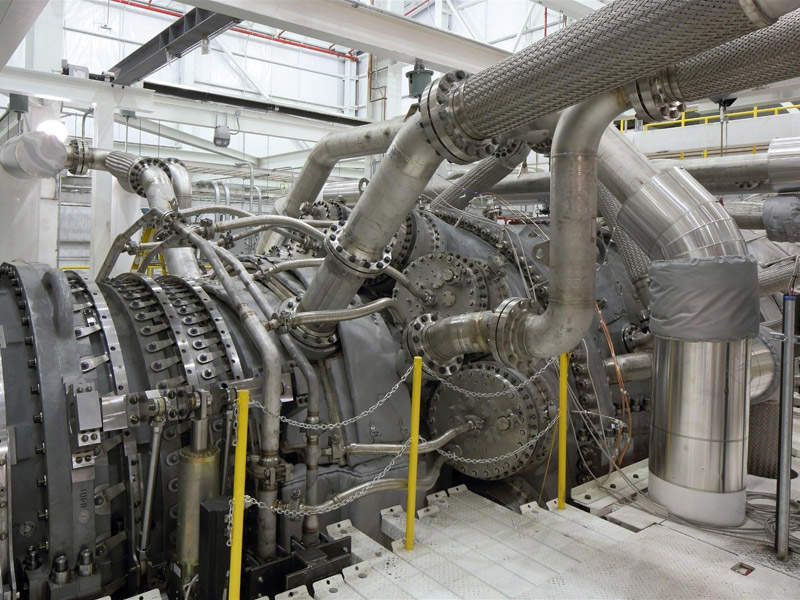

The energy centre comprises two General Electric 7HA.01 combustion turbine generators, two heat recovery steam generators (HRSGs) and one steam turbine generator.

The tallest building at the site is the HSRG building measuring approximately 120ft, which integrates a silencer for noise reduction, whereas the tallest structures are the two exhaust stacks measuring approximately 150ft each.

The power plant integrates an air-cooled condenser, which reduces the water requirements drastically. Certain water requirements, however, are supplied by the Heritage Village Water Company (HVWC) and stored in two 875,000gal water storage tanks.

The plant is equipped with dry low NOx combustion and selective catalytic reduction (SCR) systems to control NOx emissions when operating on natural gas (the primary fuel), whereas water injection with the SCR system is used while operating on ultra-low sulphur distillate (ULSD back-up fuel).

Safety systems incorporated into the design include emergency gas shut-off valves, natural gas detectors, pressure sensors to detect loss of natural gas pressure, and separation of the transformers by firewalls. Of the total project area, six acres are reserved to facilitate storm water management.

Grid connection and fuel supply

An 115kV substation was constructed at the project site. The project’s output is conveyed to the national grid via an overhead transmission line interconnecting with three existing 115kV transmission lines passing through the project site to the Connecticut Light and Power Company’s 115kV interconnection point between Baldwin Junction and Beacon Falls.

The natural gas for the project is sourced from Spectra Energy’s Algonquin Interstate Pipeline via a new interconnection pipeline. A 1.5mgal storage tank is installed to store the ULSD at the project site.

Contractors involved in the CCPP project

The engineering, procurement and construction (EPC) contractor for the project is Gemma Power Systems, a subsidiary of Argan.

NAES Corporation was engaged to operate the CPV Towantic Energy Centre in Oxford.

Benefits of the combined-cycle power project in Connecticut

The project generated 900 jobs during the construction phase and approximately 22 full-time jobs during the operation.

It is currently supplying electricity for approximately 800,000 homes in Connecticut. It will also help replace the capacity to be left void by old power plants in the area, which are at risk of retirement by 2020.

Based on the economic impact study conducted by the University of Connecticut’s Connecticut Centre for Economic Analysis (CCEA), the project is expected to contribute $7.85bn to Connecticut’s gross domestic product (GDP) during its estimated operational life of 25 years.