ANDRITZ Hydraulic Impeller Blade Adjustment in Vertical Cooling Water Pumps

In order to cater for all delivery rates and head requirements in cooling water pumps, a complete programme of impeller designs is needed, each with their own specific speed. Still, this is not always enough to cover all potential applications.

There is often a need to react to changing conditions in delivery rate and head during operation, for example if there are fluctuations in the cooling water level or differences between day and night operations. If the pump had to be shut down and the impeller blade angle adjusted manually, the downtime costs would certainly be high.

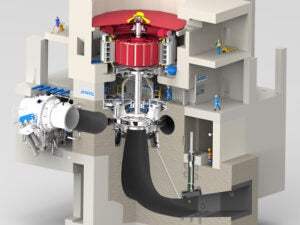

Changes in delivery rate and head can be accommodated promptly by means of speed control on the one hand, or with a hydraulic impeller blade-adjusting device on the other. ANDRITZ Pumps has drawn on its experience in turbine manufacturing and now transposed the advantages of hydraulic impeller blade adjustment to cooling water pumps.

The hydraulic impeller blade adjusting device (there is a 15° angle between minimum and maximum) is a mechanism that is easy to maintain and also guarantees reliable operations. A servo-cylinder that can be fed pressurised oil from both sides is used to rotate the impeller blades via sliding blocks and adjustable cranks. This hydraulic adjusting mechanism has been used successfully for decades in turbine manufacturing.

For further information on ANDRITZ pumping technologies for the power industry, please contact the company via the enquiry form.