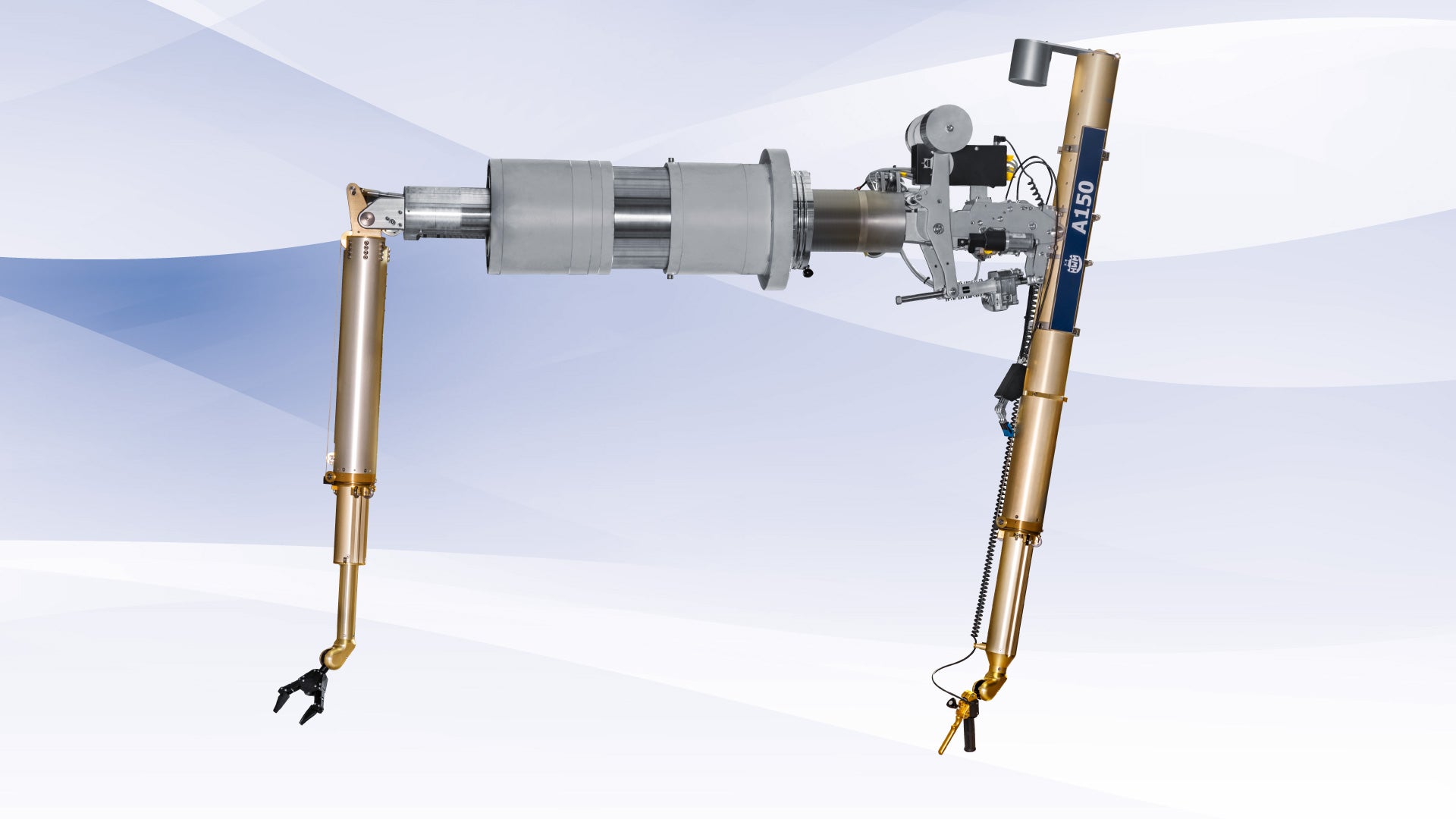

Telemanipulator System A150

The A150 telemanipulator, the latest addition to the distinguished HWM family, stands as a pinnacle of advanced remote manipulation technology. This cutting-edge system has been meticulously designed to empower operators in nuclear facilities with unparalleled precision, versatility, and ergonomic excellence.

At the heart of the A150’s innovation lies its telescoping manipulator mechanism, which incorporates state-of-the-art electric pre-positioning capabilities for the X, Y, and Z axes. This unique feature extends the system’s range of motion, enabling the working arm to access areas that were previously challenging to reach, all while maintaining the operator’s comfort and ergonomic well-being. This harmonious blend of extended reach and ergonomic optimization underscores the A150’s commitment to operator safety and efficiency.

One of the most remarkable attributes of the A150 is its remarkable weight compensation system. Engineered to perfection, this technology relieves operators of the physical burden associated with maneuvering the manipulator. By seamlessly offsetting the weight of the system, the A150 ensures a fatigue-free work environment, allowing operators to focus their energies on intricate tasks and minimizing the risk of physical strain.

The A150’s adaptability is equally impressive, as it can be seamlessly installed within wall openings of varying diameters. Whether the situation demands a diameter of 160 mm or 190.5 mm, the A150 fits snugly, ensuring efficient utilization of space while maintaining the structural integrity of the environment. This adaptability paves the way for a multitude of applications within diverse operational contexts.

Addressing the critical concern of contamination, the A150 features a detachable sleeve. This sleeve acts as a barrier, preventing dust, particles, and contaminants from infiltrating the working arm. By safeguarding the integrity of the working environment, the A150 reinforces its reputation as a reliable and hygienic tool.

The A150 extends its utility even further through its versatile configuration options. It is available in both gas-tight and non-gas-tight through-wall tube versions, showcasing its compatibility with a range of operational scenarios. Moreover, these configurations can be complemented with lead and/or biological shielding, demonstrating the A150’s commitment to safety and radiation protection.

This exceptional telemanipulator has found its natural home within nuclear facilities. Its precision, adaptability, and safety features make it an invaluable asset in the intricate and high-stakes tasks that characterize the nuclear domain. From delicate operations to tasks requiring a robust shielded setup, the A150’s adaptability ensures that it is a versatile companion for a wide spectrum of applications.

In conclusion, the A150 telemanipulator stands as a testament to Wälischmiller’s unwavering commitment to pushing the boundaries of remote manipulation technology. Through its telescoping design, ergonomic ingenuity, weight compensation, contamination prevention measures, and adaptability to various configurations, the A150 has rightfully earned its place as an indispensable tool within nuclear facilities. Its fusion of advanced features with operator-centric design principles truly sets a new benchmark in the realm of telemanipulation, elevating operational efficiency and safety to unprecedented heights.