Stokers/Grates

Detroit® RotoGrate Stoker – Air-Cooled Traveling Grate with Continuous Ash Discharge

The Detroit® RotoGrate Stoker is a traveling grate spreader stoker designed for high-ash and low fusion fuels. It features continuous ash discharge and is suitable for biomass and waste fuels ranging from low-ash poultry litter to high-ash coal. Its unique hinged bar design allows ash siftings to be discharged at the lower portion of the catenary while promoting air flow through the fuel bed. Heat-resistant grate bars are available in several material options. The system also includes automatic air seals, a high-pressure overfire/secondary air system for effective staged combustion, and thermocouple assemblies to monitor grate temperature.

Detroit® Hydrograte Stoker – Water-Cooled Grate for High Moisture Biomass

The Detroit® Hydrograte Stoker combines spreader stoker technology with water-cooled grates and automatic ash discharge, providing reliable combustion under varying load conditions. It is ideal for burning high-moisture, low-ash biomass fuels. Fine particles burn in suspension while heavier material forms a fast-burning bed. The system maintains the higher air temperatures needed to burn moist fuels without damaging the grates. The Hydrograte can minimize undergrate/primary airflow and maximize overfire/secondary air for effective staged combustion, supporting lower emissions. With few moving parts and shop-assembled modules, it offers lower maintenance, continuous operation, and reduced installation time for new or retrofit applications.

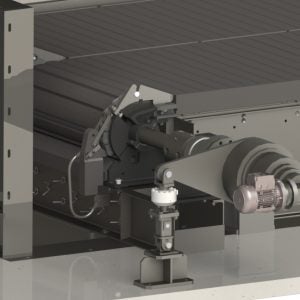

Detroit® RotoStoker VCG – Low-Profile Air-Cooled Stoker with Automatic Ash Discharge

The Detroit® RotoStoker VCG is an air-cooled spreader stoker designed to burn a wide range of fuels with efficiency. It features a low setting height, making it suitable for installations without basements. Ash is discharged automatically using intermittent grate vibration, while the fuel bed is moved forward by an eccentric drive mechanism similar to the Hydrograte. Its simple design includes few moving parts and requires no bearings or shafts. Factory-assembled modules help reduce installation time. Effective air seals between stationary and moving surfaces allow precise control of excess air and support efficient combustion.

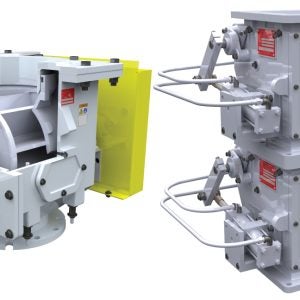

Detroit® Reciprograte Stoker – Mass Burning of Refuse and Solid Waste

The Detroit® Reciprograte Stoker is engineered for mass burning of unprepared municipal and industrial solid waste. Refuse is fed from a storage pit to a charging hopper and then forced into the furnace by a hydraulically operated ram. The grate system features alternating rows of stationary and moving grates, which push refuse through the furnace for complete combustion. Grate frames are supported by roller bearings to reduce wear. Overfire/secondary air promotes mixing of volatile gases, while undergrate/primary air is supplied separately to each grate section for optimal combustion. An automatic sifting removal system conveys material to the residue hopper for discharge.

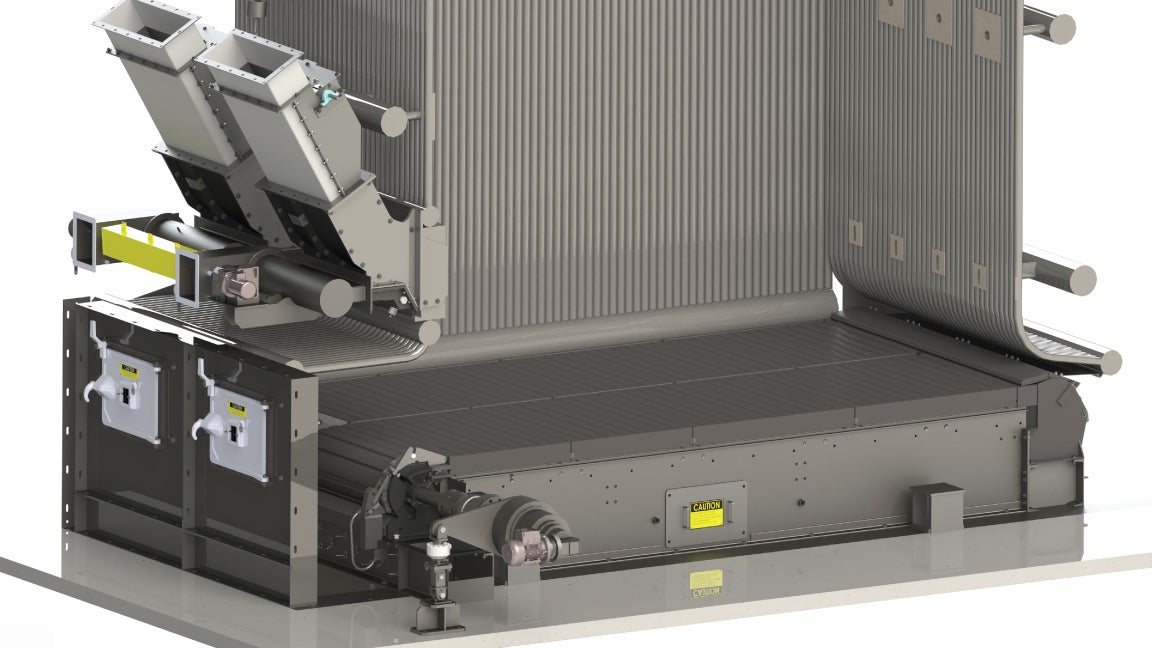

DSC-GTS Reciprocating Grate – Biomass Grate for Engineered Wood Applications

Detroit Stoker Company is the OEM of the GTS Energy Reciprocating Grate system, used in biomass combustion and gasification systems around the world, especially in MDF, OSB, and particleboard manufacturing. The inclined reciprocating grate moves fuel through drying, gasification, combustion, and burn-out zones. Ash is automatically discharged at the end of the grate. Grates are made of high-alloy materials and use air cooling for durability. This system handles a wide range of fuels, including wood chips, bark, sawdust, forest waste, and agricultural byproducts. It is conservatively sized to support capacity and reduce emissions while offering a heavy-duty design for reliable, long-term operation.

To learn more, please download our product brochures here.