Burner Systems

Detroit® Burner Systems – High-Performance Burners for Multi-Fuel Applications

Detroit® Burner Systems are designed for durability, flexibility, and reliable performance across a wide range of industrial and utility boiler applications. With fuel input capacities ranging from 15 to 290 MBTU/HR per register, these burner systems accommodate natural gas, propane, No. 2 through No. 6 oils, biodiesel, and other fuels upon request. Robust design and precise flame control minimize maintenance and ensure a long service life. Low and ultra-low NOx configurations help reduce emissions while maintaining boiler efficiency. Each burner system is engineered for reliable startup, high turndown capability, and rapid load response, making them suitable for both new installations and retrofits.

Detroit® Co-Fired Burners – Fuel Flexibility and Emissions Solutions

Detroit® Co-Fired Burners are developed to enhance the performance of existing solid fuel, grate-fired combustion systems. Designed for startup and auxiliary firing, these burners offer increased fuel flexibility and improved response to load swings. Co-firing can help reduce operating costs, support fuel switching, and recover derated boiler capacity. These burners are particularly effective in addressing emissions compliance challenges and improving overall combustion efficiency.

Detroit® Vertical Fired Burners – Optimized Conversion and Heat Transfer

Detroit® Vertical Fire Technology uses a single, upward-firing burner installed in the furnace floor, eliminating flame impingement on boiler water walls. This vertical configuration allows a single burner to deliver the input capacity of multiple side-wall burners while optimizing heat transfer within the furnace cavity. The design simplifies the combustion system by removing the need for multiple gas trains and complex burner management systems. Ideal for coal-to-gas conversions, Detroit® Vertical Fired Burners support turnkey retrofits with improved reliability, reduced maintenance, and lower capital cost.

Detroit® Packaged Boiler Burners – Integrated, Compliant, and Reliable

Detroit® Packaged Boiler Burner systems are fully integrated and factory-tested to ensure reliable performance and simplified installation. These combustion systems offer a single-source solution for burner applications, with system designs that meet both federal and state air quality standards. Built to support both new and retrofit boiler projects, Detroit® Packaged Burners deliver efficient combustion with streamlined support from one trusted provider.

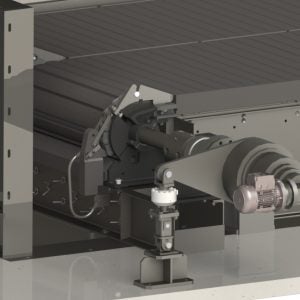

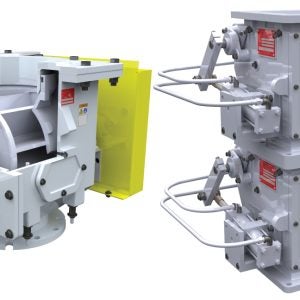

Detroit® Burner System Equipment – Pre-Engineered for Easy Integration

Detroit® Burner System Equipment includes pre-engineered fuel trains and burner management systems (BMS) designed to simplify installation, integration, and ongoing operation. Fuel trains are manufactured per NFPA54, NFPA85, FM, and ASME codes, and are available for gas, oil, pilot, and atomizing systems. These systems feature dual safety shutoff valves, precise 4–20mA fuel metering, and custom manifolds to meet specific site needs. The Burner Management Systems use Allen-Bradley PLC components, customizable HMIs, and provide full burner sequencing, diagnostics, and Ethernet connectivity for DCS integration. Both systems are available as windbox-mounted or remote-mounted to suit a variety of installation environments.

To learn more, please download our product brochures here.