Material Handling

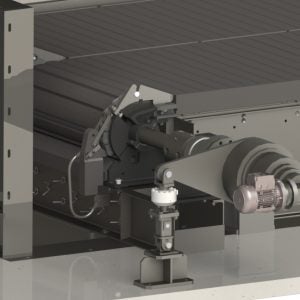

Detroit® Rotary Seal Feeders – For Abrasive and High-Temperature Materials

Detroit® Rotary Seal Feeders are engineered to handle abrasive and high-temperature materials with durability and efficiency. Constructed entirely of cast iron, these feeders include spring-loaded tension bolts for a secure air seal and oversized rotor pockets for effective material flow. Access panels allow easy internal inspection and maintenance, while heavy-duty packing glands and high-temperature packing prevent leakage at the rotor shaft. The shear pin assembly protects the drive mechanism from jamming, and external pillow block bearings ensure long service life. Rotary Seal Feeders are typically installed vertically but may operate at up to 35° angles from vertical. Available in standard and high-capacity sizes ranging from 6″ to 14″.

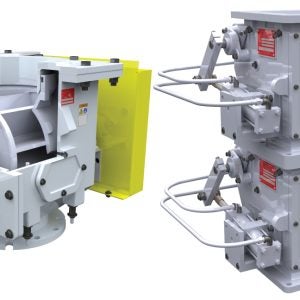

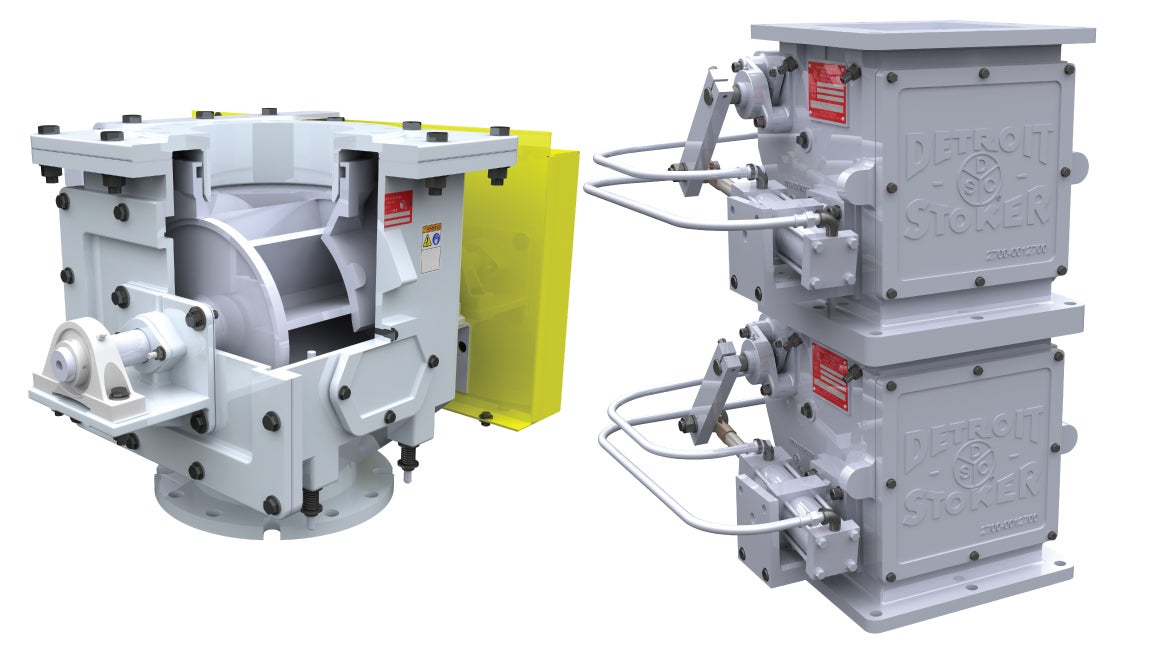

Detroit® Double Flap Airlock – Durable Material Seal for Challenging Applications

The Detroit® Double Flap Airlock is built to maintain an air-tight seal while handling hot, sticky, and abrasive materials. Designed for use in systems such as CFB boilers, kilns, silos, dust collectors, and bulk material handling applications, the airlock ensures continuous material flow using dual discharge chambers that alternate to prevent seal breakage. Built from high-temperature, abrasion-resistant materials, the valve features Detroit’s proprietary wear-resistant alloy seat and flap, and its all-cast internals are precision machined for long-term performance. A large removable access panel allows for in-place maintenance, and its full-throat design reduces the risk of bridging, making it suitable for recycling, pulp & paper, incineration, and other demanding industries.

To learn more, please download our product brochures here.