Ash Handling Systems

Detroit® Ash Handling Systems – Effective Ash Collection and Transport

Detroit® Ash Handling Systems are designed to transport ash from combustion units burning coal or solid refuse fuels, ensuring safe, clean, and economical ash disposal. These systems serve a wide range of applications including cogeneration, institutional and industrial power plants, and waste-to-energy facilities. Ash from stoker-fired, pulverized coal-fired, and fluid bed-fired boilers is conveyed pneumatically to silos for storage and scheduled disposal. Key system components include abrasion-resistant Ni-Hard fittings, offset ash intakes with hardened seats, and Detroit’s VacPak ash receiver, Ultraflo Mixer, and Clinker Grinder. Systems are supported by Detroit Stoker Company’s global network for service, maintenance, and on-site start-up assistance.

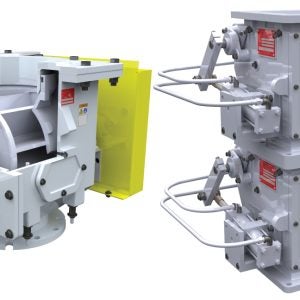

Detroit® VacPak – Compact Ash Receiver with Built-In Filtration

The Detroit® VacPak combines separation and filtration in one space-saving ash handling unit. Using abrasion-resistant materials, the VacPak includes an ash receiver and separator that removes heavy particles, while a high-efficiency filter traps fine particulate. The result is 99.9% separation efficiency. Supplied as a complete system, it includes pre-assembled dust collectors and blower units. The system eliminates the need for redundant discharge valves and reduces condensation-related maintenance issues. With side-access or walk-in doors for easy maintenance and optional filter media for various conditions, the VacPak is rated to 20″ Hg vacuum and is compatible with air lock discharge for high-capacity operations.

Detroit® Rotary Sand Classifier – Improve Efficiency in Wood Char Combustion

The Detroit® Rotary Sand Classifier is designed to enhance combustion efficiency in wood and bark-fired systems by separating unburned carbon from sand in wood char. This process reduces boiler wear, improves reinjection of high-carbon particles, and extends maintenance intervals. The classifier removes smaller, noncombustible sand particles while retaining larger, carbon-rich material for reinjection. Built for durability, the unit features heavy-duty cast iron wheels and corrosion-resistant stainless steel sizing screens available in 10–18 mesh. A quick-clamp top cover provides easy internal access, while a fan-cooled gear motor can be positioned at either the inlet or discharge end to suit various installation layouts. During downstream maintenance, an integrated diverter allows fly ash to be redirected to the waste stream, ensuring continuous operation. Available in 18″ and 27″ diameters, the Detroit® Rotary Sand Classifier supports fly ash capacities of 1,200 to 1,800 lbs./hr.

Detroit® Ultraflo Mixer – Conditioning and Blending of Ash and Sludge

The Detroit® Ultraflo Mixer is built to condition and blend dry materials such as ash, sludge, or abrasives with water. It uses a dual-shaft paddle design to provide consistent, controlled mixing while maintaining a clean operating environment. Its totally enclosed design, low-speed operation, and rugged drive system minimize wear and noise. The Ultraflo Mixer supports uniform wetting, consistent discharge, and minimal material buildup. It is ideal for new installations or as a retrofit for old drum-type conditioners and pug mills. Multiple sizes and materials of construction are available to meet specific site needs, and the unit is shop-assembled for simplified installation.

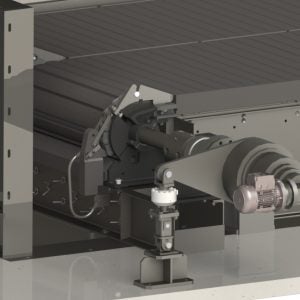

Detroit® Clinker Grinder – Built for Hostile Ash Handling Environments

The Detroit® Clinker Grinder is engineered for use in demanding environments, particularly power plants handling ash clinkers and other friable materials. Its robust design features a rigidly reinforced steel housing and Ni-Hard cast components for high wear resistance. Grinder teeth are bolted for easy replacement, and the crusher roll is supported by flanged roller bearings positioned externally for better durability. The seals are designed to withstand continuous high-temperature operation. Whether handling clinkers from combustion systems or other tough materials, the Detroit® Clinker Grinder delivers reliable crushing performance in the most challenging conditions.

To learn more, please download our product brochures here.