Fuel Distributors

Detroit® Fuel Distributors – Precise Fuel Control for Solid Fuel Systems

Detroit Stoker Company designs a range of fuel distributors to meet the specific demands of solid fuel combustion systems, ensuring precise and even fuel delivery across the stoker grate surface. From coal and biomass to bagasse and pelletized fuels, Detroit® fuel distribution equipment is engineered to deliver consistent fuel feed and optimize combustion performance. The product line includes the Air Swept Distributor, Combination Fuel Distributor, Ultrafeed Coal Distributor, Underthrow Distributor, Bagasse Triple Drum Feeder, and Pellet Metering Feeder, each designed for specific fuel types, operating conditions, and furnace configurations.

Detroit® Air Swept Distributor – High Pressure Fuel Delivery for Biomass

The Detroit® Air Swept Distributor uses high-pressure air to evenly spread biomass and refuse-derived fuels across the grate surface, both side to side and front to rear. Trajectory is controlled by adjustable air dampers, while factory-assembled components simplify installation. Built with durable materials like cast iron, stainless steel, and chromium carbide, the spout resists erosion, heat, and impact. Available in widths ranging from 18 to 36 inches, this distributor is ideal for stringy biomass, bark, bagasse, and other renewable fuels that benefit from fine, controlled fuel layering on the grate surface.

Detroit® Pellet Metering Feeder – Engineered for Pelletized Fuel Control

Detroit Stoker Company’s Pellet Metering Feeder and Distributor Spout are specifically designed to handle the unique challenges of pelletized biomass fuel. Traditional feed systems often result in flooding, erratic flow, and combustion instability. Detroit’s solution delivers consistent, even pellet distribution, preventing fuel degradation, overfeeding, or suspension burning. The system eliminates common issues such as suction-related fuel loss and slug feeding, allowing for better furnace stability and load control when using pelletized biomass.

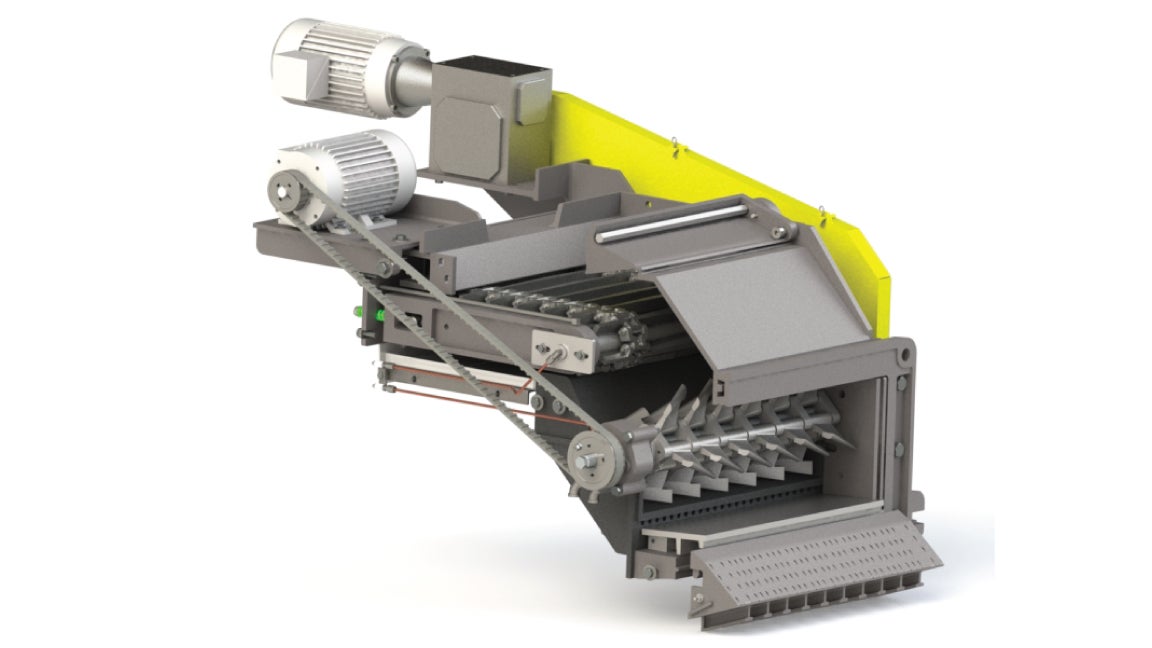

Detroit® Bagasse Triple Drum Feeder – Uniform Bagasse Feeding for Sugar Mills

The Detroit® Bagasse Triple Drum Feeder provides a steady, controlled feed rate for bagasse, the fibrous byproduct of sugarcane. Its three-drum arrangement separates and distributes the fuel while coordinating with other elements of the stoker-feeder system. Available in 30″ and 36″ widths, this feeder is ruggedly built with heavy-duty drive components and internal deflectors to prevent entanglement. The system is an ideal retrofit solution for outdated single-drum feeders in sugar mills, offering reliable fuel flow under varying loads.

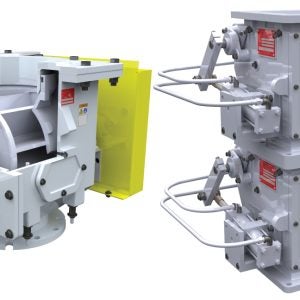

Detroit® Combination Fuel Distributor – Flexible Dual-Fuel Capability

The Detroit® Combination Fuel Distributor enables flexible combustion of both coal and biomass or refuse fuels—individually or in combination—offering operators more control over fuel costs and combustion characteristics. Designed with pivoting blades, water-cooled bearings, and an adjustable fuel gate, the system helps mitigate jams while accommodating lower quality fuels. The design supports optimal energy recovery from high-calorific industrial waste streams and enhances adaptability in mixed-fuel boiler operations.

Detroit® Underthrow Distributor – Designed for Fines and Moisture-Rich Coal

The Detroit® Underthrow Fuel Distributor is optimized for spreader stokers burning coal with high fines or moisture content. Its under-rotor discharge design allows prolonged blade contact with fuel, enhancing distribution consistency. A pneumatic plate ensures a more horizontal trajectory, helping spread fine particles across the grate bed. This model features jam-resistant pivoting blades, a rugged chain-conveying carriage, VFD-driven motors, and replaceable internal assemblies—all suited for lower-quality fuels and longer throw distances.

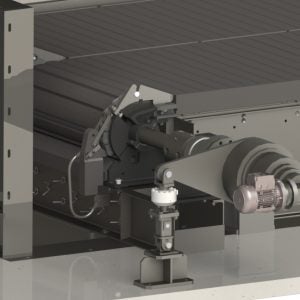

Detroit® Ultrafeed Coal Distributor – Precision Fuel Metering and Rotor Control

The Detroit® Ultrafeed is a chain conveyor distributor with independent drive systems for both the fuel metering conveyor and the overthrow rotor. This design supports precise coal distribution across the entire stoker grate surface. It allows close response to modern combustion control signals and is ideal for high-volume coal applications or system upgrades. Features include VFD-driven motors, water-cooled bearings, oversized fuel passageways, and an adjustable conveyor position for controlling feed trajectory and fuel distribution.

To learn more, please download our product brochures here.