Gruber Hermanos

Centrifugal and Axial Fans for Power Plants

Gruber Hermanos constructs customised equipment for many applications, including chemical and petrochemical plants, power generation, paper, and glass manufacturing.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Gruber Hermanos designs and manufactures customised equipment for many applications, including chemical and petrochemical plants, power generation, paper, and glass manufacturing.

Gruber Hermanos designs and manufactures customised equipment for many applications, including chemical and petrochemical plants, power generation, paper, and glass manufacturing.

The company produces high-performance centrifugal and axial industrial fans, which are designed to convey air and other fluids in clean, dirty, hot, cold, abrasive or corrosive conditions.

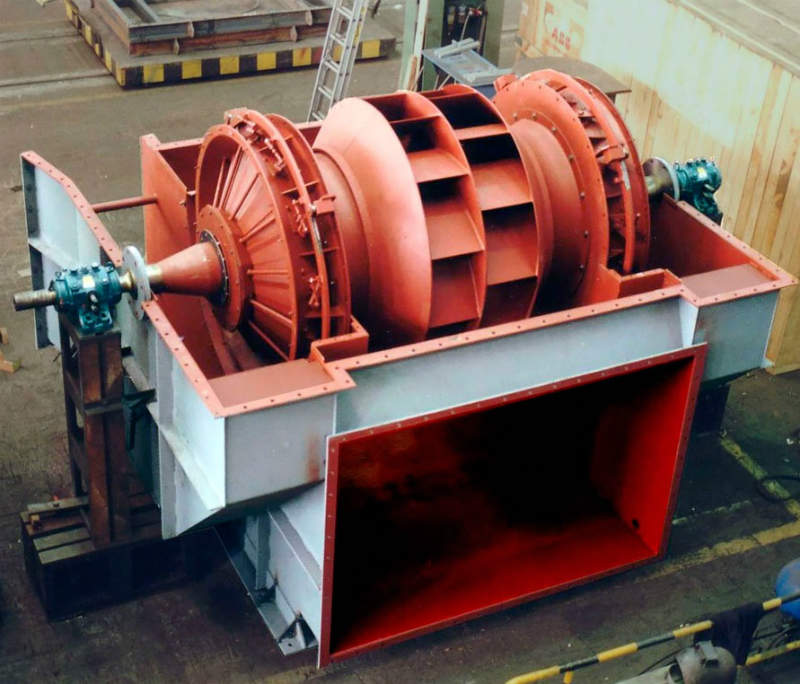

Centrifugal fans for the power industry

Gruber Hermanos’s heavy-duty centrifugal fans move air or other gases in several power facilities. Different flow and pressure ranges are available for individual customers, while each fan is designed to ensure optimised efficiency and performance in every sector.

Suitable materials and designs are selected depending on the application and the location of the fan.

Fans are manufactured for each specific application, allowing the company to comply with individual client standards. The rotating machines also require minimal maintenance.

Gruber Hermanos has developed different types of impellers, including backward-curved, backward-inclined, airfoil, radial, and forward-curved (radial-tip).

Backward-curved and airfoil impellers are used for clean air or in conditions where there are a few dust particles. They feature straight, curved or airfoil blades, depending on the application, and provide up to 90% efficiency. They achieve optimised aerodynamics, are highly effective, and produce low amounts of noise.

Radial blades are recommended for fluids that are dirty or contain a lot of particles, and work by preventing solids from clinging to them in a self-cleaning method.

Forward-curved / radial-tip blades are only intended for applications where there is a high quantity of dust, making it necessary for a design that prevents solid particles sticking to them.

Gruber Hermanos’s centrifugal fans are powered through elastic coupling, pulleys and V-belts, or direct drives.

Elastic coupling is a ‘D’ arrangement motor movement, where the impeller is fitted to a shaft that rotates on independent bearings or inside a robust bearing casing. This variety of drive is used for repetitive applications and those using hot gases.

Pulley and V-belt drives offer fan speeds that are different to motor speeds. The motor is installed close to the fan and has a common steel base.

Direct drives feature a directly mounted impeller suitable for small fans in cases where there is a low power requirement and when rotation speed corresponds to motor speed.

Single and double inlet fans for power generation

Centrifugal impellers can be manufactured as a single inlet fan mounted between bearings on a passing shaft. The assembly is placed on an elevated structure with concrete foundations, while the bearing blocks are located on lower pedestals with the drive sitting on a metal frame or over the concrete.

Double inlet fans feature an integral frame that offers support to the motor-fan assembly. The frame is fixed to a concrete base, which is connected to the lower part of the fan’s covering.

An alternative double inlet arrangement includes the fan being mounted on a passing shaft. The fan and drive are assembled on a supporting structure equipped with vibration isolator blocks, which decrease the amplitude of the vigorous forces caused by the rotation.

Impeller rotation direction and fan discharge / outlet position is chosen according to installation type.

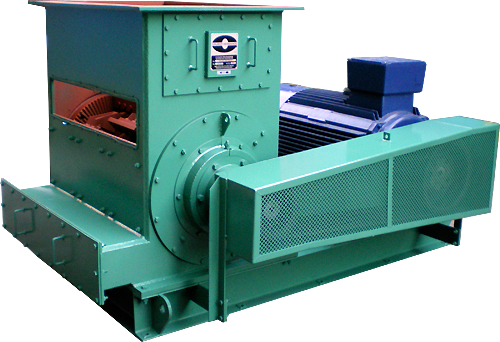

Axial fans for gas flow optimisation

Gruber Hermanos offers axial fans for optimising gas flow and where pressure differential between inlet and outlet is small. The fan has airfoil-shaped blades, which are radially arranged around the hub, and the pitch of its blades can be modified according to several operating conditions, with fan stopped.

Axial fans are fitted with guide vanes, which are placed at the inlet or outlet to reduce conveyed flow rotation and to increase energy efficiency in each application. Fans are used in ventilation systems in industrial workshops, tunnels, mining industries, ships, textile sectors, as well as cooling and prilling towers.

Main characteristics of axial fans include:

- 180mmWG for each compression stage

- 335mm-3000mm diameters

- Light alloy casting rotors with adjustable airfoil blade

- Up to 81% efficiency

Industrial fan accessories

Gruber Hermanos supplies accessories for industrial fans, including frequency converters for regulating turning speed to improve operating efficiency.

The company also provides inlet vanes, which are mainly used to control flow and pressure in centrifugal fan installations.

Inlet vanes create a pre-rotation motion for incoming flow, reducing air pressure and the difference between the impeller and gas speed.

Gruber Hermanos also provides inlet dampers, silencers, motors, filters, lubrication systems, actuators, and thermal insulators for use in axial and centrifugal fan applications.

General machinery solutions for material pulverisation and extraction

Gruber Hermanos’s general machinery division comprises micronising, grinding and milling tools used to pulverise all kinds of minerals and soft or hard materials.

The company also offers several types of mixers, including spiral, high-turbulence, biconical and blade, as well as kneaders.

Alveolar rotary valves are developed as locking elements and for extraction of granular or pulvarised products while avoiding air losses or interruptions. The valves come in three different assemblies:

- Loose shaft end (TV arrangement)

- Attached drive running vertically to the main shaft of the valve (B3 arrangement)

- Attached drive, coaxial with the main shaft (DB5 arrangement)

High-efficiency cyclones and pneumatic conveyors are also available to collect, eliminate or recover dust or particles trapped in air currents or gases produced in industrial processes.

Gruber Hermanos provides pneumatic conveying installations designed to efficiently move solids from one place to another. Air volume and pressure are calculated during the process.

Pneumatic conveying installations increase work safety and assembly flexibility, while preventing pollution during the material transportation process.

About Gruber Hermanos

Gruber Hermanos’s main focus is on meeting the needs of customers and has obtained the Lloyd’s Register Quality Assurance ISO 9001:2000 certificate of approval.

The company was established in Bilbao, Spain, and delivers products to more than 50 countries.

Contact Details

Website

Email Address

Address

Barakaldo,

Vizcaya,

48903,

Spain