Multi-Stage Axial Split Case Pump

The ANDRITZ multi-stage axial split case pump has an impeller arrangement that can be combined in different ways to fulfil different application needs.

ANDRITZ provides high-quality and reliable energy utility and turbine pumps for various applications in the power industry.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

ANDRITZ provides high-quality and reliable energy utility and turbine pumps for various applications in the power industry. The company’s products ensure the most effective use of energy and are used innovatively in the energy sector as cooling water pumps and in flue gas desulphurisation plants.

ANDRITZ’s product range includes cooling water pumps for thermal power plants, as well as standard centrifugal pumps for district heating facilities. ANDRITZ turbine pumps complete the pump programme.

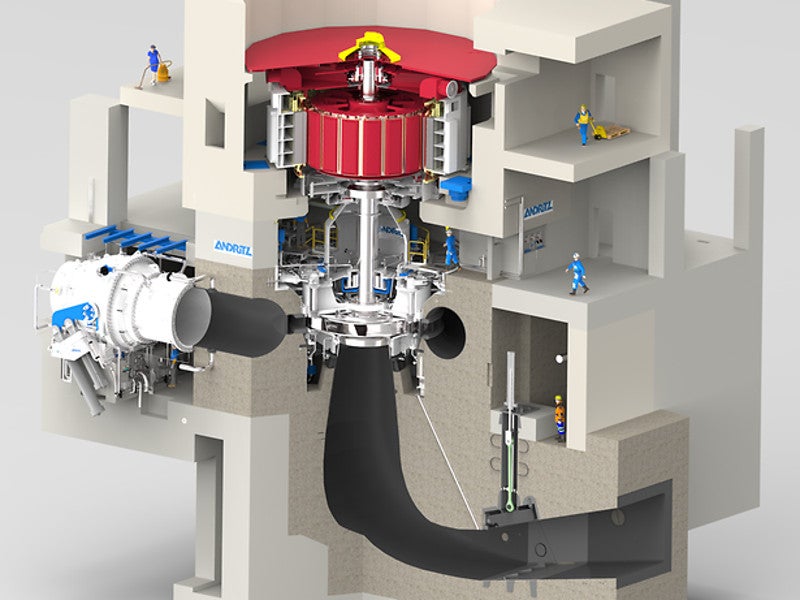

The company provides vertical line shaft pumps that can be supplied with pull-out or non-pull-out characteristics depending on customer requirements. The pumps are provided with radial, mixed flow or axial impellers, which can be fitted with blades that are either fixed or adjustable during operation.

The shaft pumps function as cooling water pumps in power plants or in water supply, and are customised for heads up to 80m and flow rates up to 70,000m³/hr.

ANDRITZ vertical volute pumps are designed with a metal or concrete volute, as well as an optional guide vane. These pumps can also be equipped with a radial or mixed flow impeller.

The volute pumps are used to cool water in power plants worldwide and are customised for heads up to 250m and flow rates up to 180,000m³/hr.

The company designs cost-effective double-suction split case pumps that have a particularly long service life and are efficient.

They have an axial split case design that makes maintenance quick and easy, while the pumps’ double-flow radial impeller and in-line casing enables horizontal or vertical installation. This allows the motor to be positioned on the right or left site.

ANDRITZ split case pumps are designed to transport cooling or circulation water in energy facilities and district heating networks.

ANDRITZ pump-turbines are a cost-effective alternative to usual generators. When running in reverse, ANDRITZ centrifugal pumps can be transformed into a mini turbine, which helps to produce a strong return on investment (ROI) by recovering and creating electrical power.

The pumps can be fitted as recovery turbines in several business applications or to supply energy to mountain refugees and forest lodges.

Besides its pumps programme for the power sector, ANDRITZ Pumps, which is part of the ANDRITZ Group’s hydro business area, develops high-quality standard and customised centrifugal pumps, as well as submersible motors and pumps for a wide range of different applications and industries.

The company has decades of experience and knowledge in constructing hydraulic technologies, guaranteeing reliable and high-grade ANDRITZ pump engineering. ANDRITZ offers a well-rounded service that includes development work, model tests, engineering design, pump manufacturing, project management, and after-sales service and training.

For further information on ANDRITZ pumping technologies for the power industry, please contact the company via the enquiry form on this page.

The ANDRITZ multi-stage axial split case pump has an impeller arrangement that can be combined in different ways to fulfil different application needs.

ANDRITZ can check all system-related parameters in power plants such as delivery flow, pressure head, and energy consumption in order to optimise your system and adapt it to any changed operating conditions.

Our commitment to research and development forms the basis for our advances in hydraulic machine manufacturing. We are currently developing and testing our pumps and turbines at five locations in Austria, Germany, Switzerland, and China.

Tamega Giga Battery is a 1.15GW hydroelectric power project located on the Tamega river in Portugal.

The 300MW Nenggiri hydroelectric power plant being developed in Kelantan, Malaysia, is the biggest renewable energy project ever being developed in the country.

The Pinnapuram integrated renewable energy project (IREP) is a combined solar, wind and pumped storage hydroelectric power project being developed in the state of Andhra Pradesh, India. It is expected to supply dispatchable and schedulable renewable energy to consumers across India.

The Ialy hydropower plant extension is being developed by Power Project Management Board 2 (PMB2).

The Hatta pumped storage hydropower plant is expected to support Dubai’s goal of diversifying its energy mix.

Kidston will be the world’s first pumped storage hydropower facility to use an abandoned mine site.

Makai Ocean Engineering’s ocean thermal energy conversion (OTEC) power plant in the US is the world’s biggest operational facility of its kind with an annual power generation capacity of 100kW, which is sufficient to power 120 homes in Hawaii.

The Zhen'an pumped-storage power project is a 1,400MW stored hydroelectric facility under construction on the main stream of Yuehe River in Zhen'an County, Shaanxi province, China.

The Rogun Hydropower Plant (HPP) is being constructed on the upper reaches of the Vakhsh River in the Pamir mountain ranges, Republic of Tajikistan.

The Belo Monte hydroelectric power plant is being built on the Xingu River in the Pará state of Brazil.

ANDRITZ HYDRO has been awarded a contract by state-owned utility Ukrhydroenergo for modernisation of the Dnipro 1 hydropower station on Dnieper River, Ukraine.

In order to cater for all delivery rates and head requirements in cooling water pumps, a complete programme of impeller designs is needed, each with their own specific speed.

If a plant's operating settings have changed, but the pumps are still set according to the previous conditions, and clients want to save energy and costs by optimising their system, ANDRITZ is the ideal service partner.