It is seldom you see a case made against batteries. Most, if not all, consumer electronics rely on batteries for power supply. Batteries in general have also long been hailed as a key driver of the energy transition, critical to energy storage as well as electric vehicles, the main contender to their fossil fuel counterparts.

The darker aspects of batteries, meanwhile, are often overlooked — for example, CO₂ emissions generated from their production and toxic waste resulting from inadequate recycling. In addition, batteries for consumer electronics present the functional inconveniences of requiring constant recharging or replacement.

Despite these environmental and practical flaws, the battery boom shows no signs of slowing down. The consumer electronics lithium-ion battery market was valued at $4.9bn in 2023 and projected to reach £8.2bn by 2032, according to 360 Market Updates.

However, US-based solar start-up Ambient Photonics now challenges the throne, having developed the world’s most powerful low-light energy-harvesting solar cells to overcome the shortcomings of batteries. Speaking to Power Technology, the company’s CEO and co-founder Bates Marshall, who has 20 years of experience in solar and a decade in semiconductors, explains the potential – and need – for solar cell technology to replace batteries in electronic devices.

Jackie Park (JP): Tell us about Ambient Photonics and your solar cell technology.

Bates Marshall (BM): With most new power additions to the grid being renewable, usually solar or wind, our team had the idea to apply the same approach to the electronics industry, in the service of replacing or eliminating batteries.

The technology that we have developed is low-light, indoor solar to power electronic devices. The technology was originally developed at the Warner Babcock Institute for Green Chemistry, which developed the key materials that became the cornerstone of our breakthrough.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataSolar-powered products have been around for a long time… There’s first generation solar, which is your classical silicon-based technology. The $200bn outdoor solar market is dominated by silicon-based technologies, with very few exceptions.

Second generation was the era of thin film photovoltaics (PVs) – mainly, copper indium, gallium and selenium – but most [start-ups] have failed, with the exception of First Solar. Then, third generation is emerging from the labs now. The three most prominent technologies are perovskite, organic PV and dye-sensitised solar cells (DSSC).

Our technology is DSSC. DSSCs have also been around for a long time but never successfully commercialised. They were developed from materials that are abundant in nature and were thought to be made cost-effective at scale, but DSSCs, in comparison to silicon technologies, lacked appropriate stability in outdoor applications. They had decent performance in indoor, low-light conditions but not sufficient to convince investors.

But my co-founder, Dr Kethinni Chittibabu, invented these novel molecules, put them into a DSSC architecture and found that the performance was around four-times greater than conventional indoor [DSSC] solar cells. That was the start of our journey.

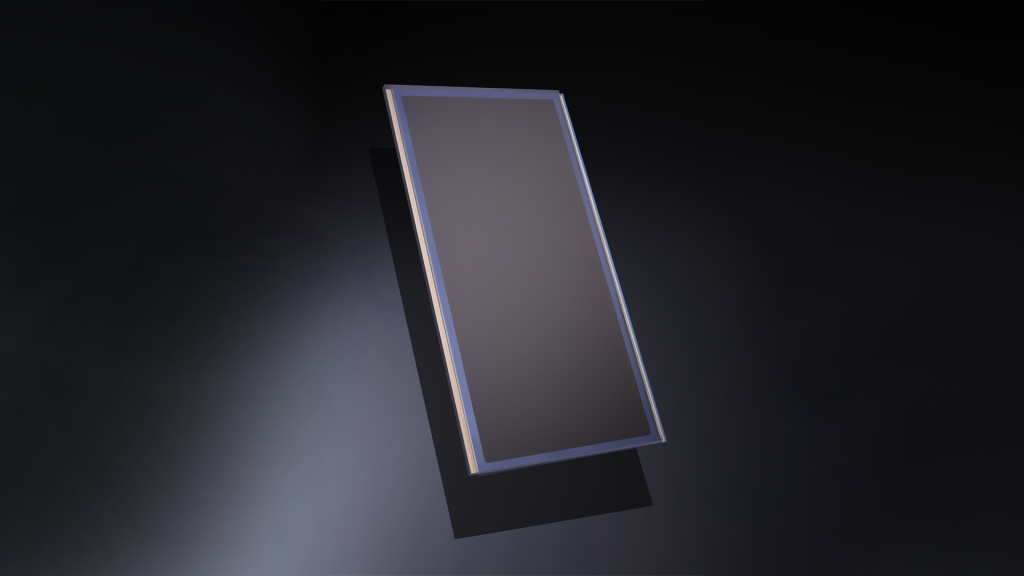

Our solar cell looks like a black rectangle glass. We use a 1mm-thin glass substrate and deposit a metallic semiconductor, which is the carrier for our dyes. Then we coat the material with our dyes, which do the heavy lifting of releasing the electron and generating the current flow, and encapsulate it with a cover sheet.

JP: What differentiates your technology from other solar cell technologies currently on the market?

BM: It’s a combination of high power, which opens the market, but also low cost, which is compatible with the economic realities of the electronics industry. I’ve learned a few lessons from outdoors PV, which is that commoditisation of the value proposition can be brutal. What really matters is levelised cost of energy, everything else being equal.

That is the differentiation with our product. We have the highest power in the market by a huge stretch – four-times greater power than with silicon. We have the same power density, even slightly higher in lower light, as the famous gallium arsenide, one of the champion materials used extensively in the space satellite industry.

Yet, our cost basis is about the same as a commodity amorphous silicon. An Ambient cell might sell to a customer in an electronics market for $1.50, while a gallium arsenide cell would sell for $25.

JP: You’ve previously stated that “batteries are dead”. What is your case against batteries?

BM: I had been working in solar for a long time and was aware that solar has not only a sustainability focus, but also a critical focus on economics. So, creating a product that is not just better from a sustainability outcome perspective – eliminating the carbon footprint of batteries – but also in design, usability and functionality – a device that runs forever – became our technical and emotional hook.

Eliminating something bad is a key motivator. Batteries, of course, are the incumbent power source in the electronics industry. Historically, there hasn’t been much attention on the problems of batteries. But if you peel the onion… you realise that devices are volumetrically defined by the batteries that are inside, making the product huge and clunky. Most devices are just plastics and circuit boards wrapped around large batteries. Getting rid of this big piece could open new design considerations.

We also know that most of the large electronics companies in the world have made so-called net-zero pledges, but the production of devices intrinsically has carbon, meaning manufacturers are just writing cheques for carbon offsets. That’s the dirty secret of carbon-neutral devices – they aren’t carbon neutral.

The carbon accounting process begins with a life cycle assessment (LCA)… and if you look at the pareto of carbon in these devices, as given by LCAs, most of the time the battery is the highest carbon-containing component. So, if you really want to be honest and do it cost-effectively, removing the battery and replacing it with a lower carbon-containing energy source is the way to do that.

There has also recently been more attention from regulators on the problems of batteries, mainly around their end-of-life issues. In most jurisdictions around the world, it’s illegal to throw batteries into the trash. However, just a tiny fraction, less than 1% of batteries, end up in the recycling programme, instead going to toxic trash.

This leads to millions of tons of waste globally going into landfills and causing all kinds of environmental catastrophes. There are options to reduce toxic waste, but our customers are acting by eliminating batteries, removing the problem completely.

JP: Regardless of this case against batteries, why have battery-free alternatives such as your own not become popularised yet?

BM: The main reason is real estate related. In outdoor solar, there is a distribution of technologies, with high-efficiency and low-efficiency panels in the market, and solar manufacturers are always looking for ways to increase efficiency. However, the market doesn’t always solve for efficiency.

Instead, the market solves for efficiency only in applications where the area is constrained. For example, in rooftops in Japan, you find very high-efficiency panels, and in power plants in the US desert, you find lower-efficiency panels.

Electronics devices are fundamentally very area constrained – they need to be able to be powered and used indoors. Our technology creates the opportunity for the first time for solar to replace batteries to power these devices.

JP: When do you expect battery-free alternatives to become commercialised with large-scale application?

BM: We will bring to market some of our first products this year. With investment, we’ve been able to build the means of production and get into our first factory, and that factory is opening right now.

It took us some time, however. Our factory can make tens of millions of units per year – big numbers – but our customers [electronics manufacturers] make hundreds of millions of devices per year, and we’re addressing markets that are chipping in billions of units per year. Navigating this is a challenge, and it takes time. So, the first impact will be this year, and next year should be a big breakout year for the tech.

JP: Can your solar cell be incorporated into all kinds of currently battery-reliant devices or are there limitations?

BM: There are certainly limitless applications to the tech, but we have to be realistic about the available energy. It’s a question of the size of the energy available, the power budget of the device and how much we can practically fit into the device.

The amount of illumination that’s present in the indoor environment is three orders of magnitude lower than outdoors. Being practical about the energy density of the photons bouncing around indoors, we are not going to be able to power high-power devices like laptops, notebooks, tablets or phones.

However, there are interesting applications where we can help. Many [high-power] devices these days go to sleep and save power when they’re not being used, awaiting activation by way of a wake word. We can power those wake word detection circuits very effectively and keep the device on hibernation mode. When devices are plugged into the mains power, they’re drawing what’s called vampire power, or quiescent current, from the wall while on standby. So, we may not be able to completely power these devices, but we can at least do our part to reduce that vampire power.

We find greenwashing in the electronics industry quite a bit. There are power banks with solar cells that claim, ‘you can charge this with indoor light’, but if you do the math, you find it’s never going to work properly, or you’ll need outdoor illumination. We’re very careful not to get into this category of greenwashing, which means acknowledging the upper bound on the application of our technology. Our argument is fitness for use in low-power Internet of Things and devices, which itself is a market with tens of billions of units, leading to a huge e-waste problem. That’s the specific problem that we’re aiming to solve.