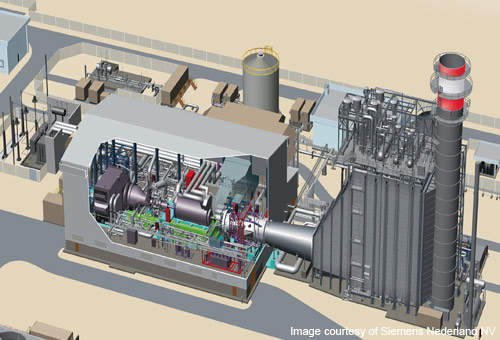

Enecogen power station is a combined cycle gas turbine (CCGT) project currently under construction at Pistoolhaven in Rotterdam’s Europoort industrial area, Netherlands.

The plant will have the capacity to generate approximately 870MW, powering about two million households. The plant will be highly flexible and have an efficiency of 59%. It will be one of the most environmentally friendly fossil-fuel power projects in Europe.

Enecogen is a partnership between utilities Eneco Energie and Dong Energy. Each has a 50% stake. Construction of the plant started in May 2009 and the plant is scheduled to start operation in late 2011.

Development

There has been a lack of major investment in new power plants in the Netherlands for almost 11 years. The Enecogen power project will improve electricity supply while reducing pollution. The plan for the gas-fuelled plant was originally conceived by Eneco and International Power in 2005. The joint venture was formed in June 2006. Electricity produced was to be completely purchased by Eneco.

In April 2009, however, Eneco made a strategic decision to buy only 50% of the power from the project for Dutch supply. International Power withdrew from the project (a mutually agreed decision) by selling 45% of its stake to Dong Energy for €12m. Dong bought a 50% of the Enecogen plant and partnered with Eneco for the construction. The Danish utility invested kr2.5bn (€335.9m) in the project.

Location

Stenenterrein was chosen for the plant because of its ideal conditions for electricity production. The Rotterdam port offers cooling water and energy savings. It also enables efficient utilisation of CO2, heat and heated cooling water emitted from the plant through integration with surrounding industrial facilities. Stenenterrein is close to high-pressure gas and high-voltage grids.

Contract

In April 2009 the turnkey contract for the Enecogen plant was awarded to Siemens for almost €700m. The engineering, procurement and construction (EPC) and long-term maintenance contract includes two single-shaft 435MW trains of SCC5-4000F 1S CCGT configuration.

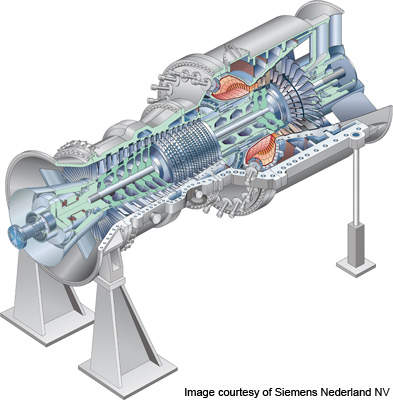

The main components of each train are a SGT5-4000F gas turbine, a SST5-5000 steam turbine and a hydrogen cooled generator. The steam turbine is of KN type with a 2 x 12.5m2 LP exit area. Siemens will also provide all the mechanical equipment and electrical and control systems for the project. The boiler building and drum type heat recovery steam generators (HRSG) will be supplied by subcontractor NEM and BAM will provide the cooling cycle. Various subcontractors will be employed by Siemens for the construction of the plant. The main equipment will be installed at the site in the third quarter of 2010.

Other contracts

In March 2007 Enecogen partnered with LionGas LNG Terminal, a subsidiary of 4Gas, an adjacent project at the site, for energy efficiency and CO2 reduction. The partnership enables efficient usage of residual heat energy from the plant.

It will be used to heat the liquefied natural gas (LNG) of the 4Gas project, enhancing efficiency. The companies will also cooperate in construction of the allied works of the projects. By April 2009 piling work at the plant site and road and infrastructure were completed.

Gas Transport Services, the national transmission operator, is responsible for the fuel gas connection and gas transport capacity. The 36in-wide and 3.12km-long new fuel gas pipeline connection contract was signed by LionGas in November 2008. The pipeline will also be used by the Enecogen plant and is scheduled to be completed in the first quarter of 2011.

Technology

The power station is more efficient (59%) than most coal-fired power stations (45% efficiency). At the Enecogen plant, the gas turbine, steam turbine and generator are connected by a single shaft principle. The power from the plant is produced in two stages to enhance efficiency and reduce emissions. In the first stage, gas is combusted to rotate the gas turbines at high speeds. They are coupled with the electric generator.

The second stage includes the heat recovery steam generator (HRSG), which utilises the hot gases produced in the gas turbine to heat a closed-loop water system and generate steam. The steam powers the turbine rotations and is linked to the generator. The combined cycle process of the two stages thus produces power with greater efficiency.

A synchronous self-shifting (SSS) clutch between the steam turbine and generator provides flexibility and reliability.

Grid network

In 2007 Enecogen signed an agreement with TenneT, a Dutch state-owned national transmission system operator, for connecting the project with the high-voltage national electricity grid network. Joulz is responsible for connecting the plant to the grid. The high-voltage connection is scheduled to be implemented in the first of 2011.

Environmental Impact

The Enecogen environmental impact report received environmental and cooling water system permits from environmental service organisation DCMR Milieudienst Rijnmond and Rijkswaterstaat in November 2006. It also received permits from the public works, ministry of transport and water management authority for discharge of cooling water.

The plant will use techniques such as selective catalytic reduction, DeNOx and installations to lower the nitrogen oxide (NOx) emissions by 80% (to less than 10ppm). CO2 emissions will be lower due to the plant’s high energy efficiency. It also has low noise levels.