Permasense is the world leader in integrity monitoring systems, particularly for pipes and pipework in the power sector.

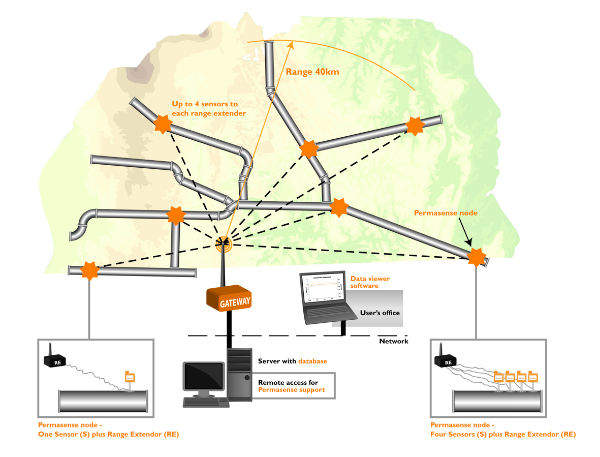

The Permasense system delivers real-time data-to-desk measurements of pipe wall thicknesses from practically anywhere in the facility, including inhospitable and inaccessible environments.

Monitoring solutions for corrosion and erosion

Permasense manufactures sensor systems for detecting and monitoring corrosion and erosion in the power sector. This ensures that these ever-present threats can be efficiently and cost-effectively monitored, planned for and dealt with.

Pipes and pipework in power plants can corrode and erode over time with constant or varying use and load.

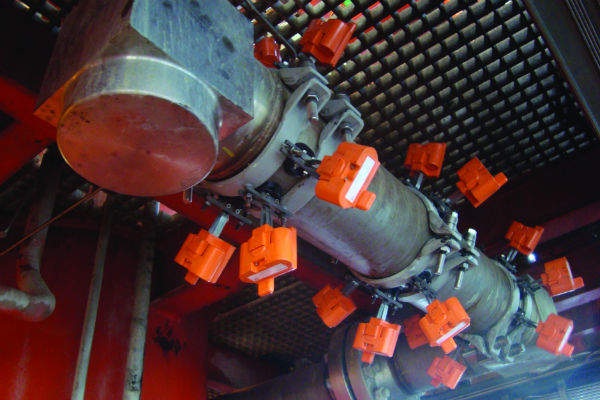

Non-intrusive sensors for measuring thickness of pipe walls

The Permasense system consists of non-intrusive sensors that measure the wall thickness of the metal in real-time. The sensors are permanently affixed to pipework and can be operated at temperatures up to 600°C (1100°F). They are battery-powered, deliver their measurements wirelessly and are designed to work in extreme conditions.

Sensors wirelessly transmit measurements to a receiver that directs it to the plant operator’s office. The information provided by the system gives a real-time view of the integrity of the pipework, as well as showing the rates of erosion or corrosion.

Heat sensors for pipes in power plants

Flow accelerated / assisted corrosion in steam systems of power plants can erode metal quickly. Monitoring the pipe thickness can allow operators to make better-informed decisions that could prevent a potential unanticipated shutdown.

Permasense sensors also have instruments for gauging heat and accurately tell operators the current temperature of pipes. This is also added to the database and can be tracked over time.

High-quality measurements enable better decisions for enhanced profitability

Knowing the condition of pipes and pipework in facilities is extremely important, both in terms of operational practicalities, safety concerns and profitability.

One common issue in power plants is that of flow accelerated / assisted corrosion (FAC), which can erode metal quickly. Monitoring the pipe thickness while the plant is online can allow operators to make better-informed decisions that could prevent a potential unanticipated shutdown.

Usually, inspections are performed during shutdowns, as online inspection is either prohibitively expensive or simply too dangerous.

The Permasense system delivers high-quality measurements at a frequency that enables corrosion or erosion to be detected, monitored and mitigated, all with the facility in operation.

The knowledge gained can be used to operate the plant more flexibly, for example, by varying the load. It can also be used to better plan for shutdowns by, for example, pre-ordering components for replacement instead of having to wait to find the issues during the inspection phase of the shutdown.

Permasense is a solution for operators who want to operate their plant to its full potential.

Continuous thickness measurements allow water chemistry to be adjusted interactively to optimise and hopefully eliminate the rate of corrosion.