Engineered Products & Solutions Ltd

Rubber Bellows, Steel Compensators, Flexible Hoses and Expansion Joints

Engineered Products & Solutions Ltd offers a full range of high quality rubber bellows, steel compensators and flexible hoses; it is the sole distributor for STENFLEX within the UK and Ireland.

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Engineered Products & Solutions Ltd offers a full range of high quality rubber bellows, steel compensators and flexible hoses; it is the sole distributor for STENFLEX within the UK and Ireland.

Engineered Products & Solutions Ltd has been awarded the three prestigious certificates for ISO9001, ISO14001 and ISO18001, which incorporate quality management, health and safety, and environmental management systems.

EP&S directors have more than 40 years combined experience in providing engineering solutions to a variety of clients. We cover the UK, Ireland and all major markets in the Middle East.

Our products are used in a wide variety of industries and applications, from HVAC systems in the construction industry to power generation, the Ministry of Defence, shipping, and petrochemical, as well as food and agricultural equipment.

Flexible pipe connections for construction and engineering applications

For more than 40 years, STENFLEX has been one of the world’s leading suppliers of flexible pipe connections for construction and engineering applications. These components are used in power technology, industrial equipment, shipbuilding, gas and water supply systems, as well as domestic engineering.

Expansion joints and industrial hoses

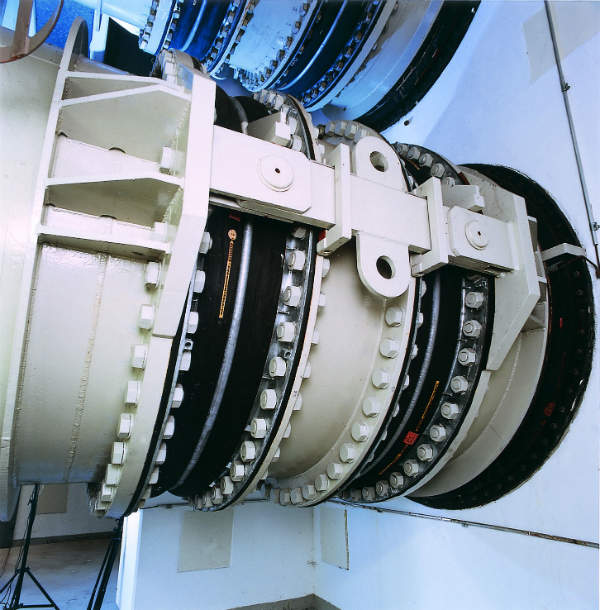

STENFLEX develops, manufactures rubber and steel expansion joints, PTFE and fabric expansion joints, pipe connectors, hoses, swivel joints and rubber-metal bearing components.

Our range of expansion joints and industrial hoses includes products with nominal diameters from 15mm to 3,600mm, nominal pressure ratings up to PN 40 (swivel joints up to max. PN 420) and temperature resistance ratings, from -196°C to 900°C suitable for all solid, liquid and gaseous media.

Characteristics of all STENFLEX products include:

- A high-level of operational safety and reliability

- A high-level of movement compensation

- High-pressure and temperature resistance

- Tested vacuum stability

- High-resistance to various media

- Extremely long service life

- High efficiency

In addition to the STENFLEX standard product programme, customised compensators are also available upon request.

Connections parts (that deviate from DIN) such as ISO, ANSI, VG and SAE standards, are also available.

Steel expansion joints

STENFLEX steel expansion joints offer qualities such as:

- Type (universal / lateral / angular expansion joints)

- Pipe connection type (flange, welding end or threaded connection)

- Material quality of the bellows (rated to the media)

- Bellows structure (rated to movement, pressure and temperature)

- STENFLEX expansion joints are delivered ready for installation in nominal widths of DN 15-DN 3400 and nominal pressure rates up to PN 25. A wide range of materials is used, with temperature resistance from -196°C to 900°C

Rubber expansion joints

STENFLEX rubber expansion joints differ according to the following criteria:

- Type (universal / lateral / angular expansion joints)

- Pipe connection type (flange, thread)

- Rubber quality of the bellows (rated to the media)

- Bellows structure (rated to pressure and temperature)

STENFLEX rubber expansion joints are also delivered ready-to-install in nominal widths of DN 20-DN 3600 and for nominal pressure rates up to PN 25. A wide range of materials is used, with temperature resistance up to 110°C.

PTFE expansion joints

STENFLEX PTFE expansion joints are particularly suitable for aggressive media. PTFE is resistant to almost all chemicals and solvents.

STENFLEX PTFE expansion joints are used in machinery, industrial equipment and piping systems. They are established in industry sectors such as chemicals, process engineering, foods, beverages, pharmaceuticals, waste and disposal technology, as well as IT.

Swivel joints

STENFLEX swivel joints are used in applications involving liquid and gaseous media. They can be used as flexible pipe connectors in the most demanding conditions and can withstand extreme temperatures and pressures.

STENFLEX swivel joints are highly suitable for absorbing oscillations. Swivel motions can be handled, as well as complete rotation at low speeds.

Our swivel joints can be used in a wide range of applications, including:

- Loading and swivel arms

- Pipe joint tongs

- Hydraulic fluid supply lines

- Mill and rolling stands

- Sewage treatment aeration tanks

- Filling applications in open areas

- Steel and rolling works

Industrial hoses

STENFLEX hoses provide safe connections whether in process technology, offshore applications, mechanical engineering, building engineering or as part of supply systems.

Functions include:

- Noise and vibration transmission

- High-absorption of lateral and angular movement

- Compensate for installation inaccuracies

- Reduce thermal and mechanical tension

- Quality and service

STENFLEX flexible pipe connections are designed and dimensioned in compliance with national and international regulatory standards. The optimum quality of STENFLEX products has been confirmed by approval bodies and independent test institutes worldwide.

To ensure that our products and processes continue to remain at a consistently high level in future, we work in compliance with ISO 9001:2008.

Many of our products have achieved KTA 1401 approval for use in nuclear plants. STENFLEX has attained all major and approved national and international manufacturer certificates, component tests and special certificates of competence. Our production processes are based on the ISO 9001:2008 quality management system, which has been used throughout our organisation for many years.

Contact Details

Website

Email Address

Address

Halesfield 17,

Telford,

Shropshire,

TF7 4PF,

United Kingdom