Kockum Sonics

Superior Cleaning by Sound

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Kockum Sonics pioneered sonic cleaning technology more than 35 years ago. Kockum Sonics’ origin was at the Kockum Shipyard where we have been developing and supplying the acoustic signalling systems for more than 100 years.

We noticed that onboard a ship, ash would fall off the chimney when the ship’s whistle sounded. Realising the advantages of using sound for cleaning, Kockum Sonics has been constantly developing and improving sound cleaning products for various

applications ever since.

Our developments have always been made in close cooperation with our end users, as well as with boiler, filter and catalyst manufacturers.

SONIC CLEANING PRODUCTS

The Kockum Sonics range of sonic cleaning products includes:

- SONOFORCE® – Kockum Sonics’ series of pneumatic audible sonic horns

- INSONEX® – Kockum Sonics’ series of pneumatic infrasound generators

- PULSATOR® – Kockum Sonics’ pneumatic silo-fluidizing discharge system

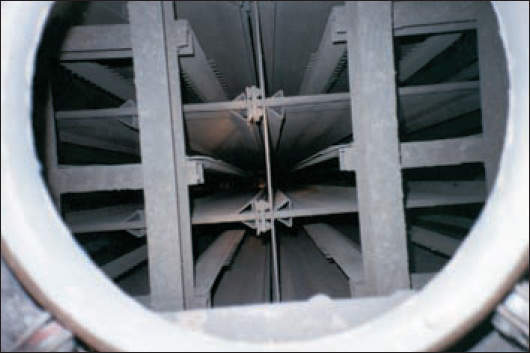

SONIC CLEANING FOR BOILER CLEANING

Kockum Sonics’ sonic cleaning can be used to clean a wide range of boiler applications, including super heaters, re-heaters, economizers, SCR-catalysts and air pre-heaters. Our sonic soot blower is, in most cases, a better alternative to steam soot

blowers, steel ball cleaning or air-lance cleaning.

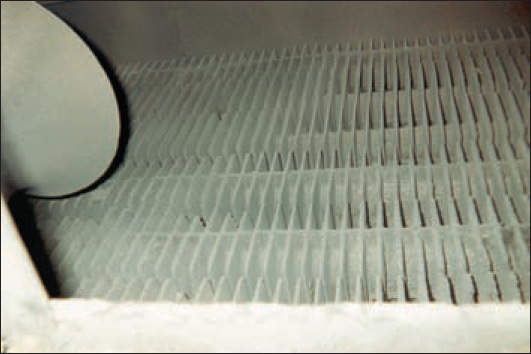

SONIC CLEANING FOR FILTER CLEANING

Sonic cleaning is also ideal for cleaning textile filters, electrostatic precipitators, cyclones, hoppers and ID fans. Our sonic cleaning products are, in most cases, a better alternative to pulse-jet cleaning, reversed-air cleaning,

rappers and hammers.

ECONOMIC BENEFITS FOR BOILER AND FILTER CLEANING

Sonic cleaning provides numerous economic benefits for boiler and filter cleaning. These include:

- Constantly cleaned heat-transferring surfaces

- Increased power output

- Higher fuel efficiency

- Improved heat transfer and filter efficiency

- Decreased maintenance and operation costs

- Improved lifetime on boiler tubes and filter bags

- No dead spots – sound waves reach everywhere

- Easy to retrofit

SONIC CLEANING FOR FOOD AND FINE CHEMICAL APPLICATIONS

Kockum Sonics’ sonic cleaning products have been successfully used for spray driers, filters, ductwork, and silos for the food and fine chemicals industry.

SILO DISCHARGE SYSTEM

Kockum Sonics’ fluidising system for handling bulk and powdery material uses a pneumatic pulsator. The pulsating air is injected through panel activators into the powdery material.

SONIC HORNS FOR INDUSTRIAL ALARM AND CIVIL DEFENCE

Kockum Sonics also provides a wide range of sonic horns for industrial alarm and civil defence. These sound emitters are either electronic or pneumatic and fulfil all specified regulations for these types of product.

The alarm products are also used for tsunami warning systems and port facilities.

Our alarm products are:

- TYFON® – Kockum Sonics’ series of pneumatically-operated sonic horns

- TYFONIC® – Kockum Sonics’ series of electronically-operated sonic horns

- DELTA® – Kockum Sonics’ series of electronically-operated sonic horns

SCHALLREINIGUNG FÜR KESSEL UND FILTERANLAGEN

Kockum Sonics, ist der ursprung der Hörbaren Schallreinigung und Infraschallreinigung. Für einsätze im bereich von überhitzer 1250C, Katalysatoren, Luftvorwärmer, Elektrofilter, Schlauchfilter und Silo. Kockum Sonics schallsender und pulsator systeme hat für mehr als 35 jahr im betrieb sein.

SILOENTLEERUNG

Kockum Sonics Fluidisierung für Bulk und Pulver hantierung brauchen einem vollpneumatischen Pulsator. Die pulsierende luft wirt injiziert und dann mittels Aktivierungsflächen im Pulvermaterial verteilt.

SCHALLSENDER FÜR ALARM UND CIVILSCHUTZ

Kockum Sonics bietet Warnsystemen mit Elektronischen – und Pneumatischen – Schallgeber an die entsprechen Forderungen.

Contact Details

Website

Email Address

Address

PO Box 1035,

Malmo,

SE-212 10,

Other,

Sweden