Surface Protection Solutions for Mission Critical Equipment

Integrated Global Service provides surface protection solutions for challenging metal wastage problems in mission critical equipment worldwide.

Based in Virginia, US, Integrated Global Services, Inc. (IGS) offers surface protection solutions to clients on a global scale.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Integrated Global Services (IGS) provides turnkey surface protection solutions that improve boiler reliability and increase plant availability. IGS’s proprietary High Velocity Thermal Spray (HVTS) cladding and SMARTGard® systems:

IGS leverages decades of experience with over 500 CFB boiler High Velocity Thermal Sprayed (HVTS) cladding applications to stay at the forefront of maximizing run time and minimizing outage frequency and cost for CFB boilers globally.

IGS provides corrosion-resistant metal alloy protection for waste incinerators, biomass, and waste-to-energy boilers. Fuel flexibility in these boilers offers related cost reduction but results in boiler corrosion. Chlorine, dew point and hot molten salt corrosion can be addressed with the application of IGS high nobility cladding.

With more than 25 years of applications around the world in Pulverized Coal (PC) Fired boilers, IGS has developed proven solutions to extend the life of boiler tubes providing a reliable, long-term solution with significant cost and time savings to its customers. The IGS HVTS cladding has been recognized as the gold standard to resist fireside corrosion in high-temperature sulfidation environments. As only one example, IGS HVTS was proven the best product in some of the most intense conditions in a 39,000-hour test in a 1,300 MW supercritical boiler by the Electric Power Research Institute (EPRI).

The IGS SMARTGard® approach has been developed over four decades by working closely with hundreds of CFB operators and OEMs. What makes this solution so smart?

Integrated Global Service provides surface protection solutions for challenging metal wastage problems in mission critical equipment worldwide.

Extending the life of the tube is possible with the use of added material to the outside diameter (OD) surface of the tube, with Weld Overlay or High Velocity Thermal Spray (HVTS) Cladding. The purpose of adding material to the tube is to extend its useful life, ultimately preventing panel replacement.

Based in United Kingdom, Drax Power Plant has a capacity of 3,906 megawatts (MW) and produces around 14 terawatt-hours (TWh) of power a year, 96% using compressed wood pellets, a form of sustainably sourced biomass.

Over the last 25 years, the plant owner utilized weld overlay to protect boiler tubes against erosion. They have been using both carbon steel weld overlay and stainless steel overlay. They were applying more weld overlay over the same exact areas, building thickness back up every outage.

IGS’s High Velocity Alloy Cladding (HVTS) solutions upgrade existing metallurgy to higher alloys that provide a barrier to mitigate corrosion and / or erosion in mission critical equipment around the world.

Boiler reliability has become one of the main challenges with the advent of efficiency advances in Waste to Energy industry.

The IGS HVTS claddings have been proven around the world to address severe corrosion and erosion problems in utility boilers, resulting in significant cost savings by preventing tube replacement and increased unit availability & reliability.

CASE STUDY | Sulfidation corrosion - reduced atmosphere corrosion.

Case study: Straw was added to the fuel mix of two CFB boilers originally designed for coal firing, leading to chlorine corrosion.

To read more please download this free whitepaper.

In the mid 2000s, a US power utility owner and EPRI performed a long-term study to determine if thermal spray technology would protect the sidewall tubes (adjacent to burner levels) from thinning caused by reduced sulfidizing atmospheres.

Case study: Corrosion and erosion mechanisms were both major contributors to tube wastage in this biomass CFB Boiler, burning waste/biomass.

There are several reasons why boilers may suffer from corrosion. The types of boilers that IGS works within the Waste-to-Energy (WtE) and wider power industry, include: Circulating Fluidized Bed (CFB) Boilers Pulverized Coal (PC) Fired Boilers Bubbling Fluidized Bed (BFB) Boilers Grate Boilers

IGS today published its first Environmental, Social, and Governance (ESG) report. The report outlines the company’s ESG commitments and the environmental and social impact created by its global operations and innovative products and services.

All process heaters operate at high temperatures and are constructed with process tubes inside a refractory-lined enclosure, which is heated by radiant heat from gas-firing or, less commonly, oil-firing.

In the world of industrial applications, where precision and innovation meet the demands of modern manufacturing, one challenge stands as a formidable obstacle—hexavalent chromium exposure.

Energy derived from burning waste (Waste to Energy, WtE) and biomass is growing rapidly as countries seek to increase green power generation, avoid landfill and recover the captured energy.

Rich Crawford, CEO and president of Integrated Global Services (IGS), is confident in the company’s growth prospects, which are driven by strategic acquisitions, a strong business culture focused on talent development and effective execution of its value proposition.

Integrated Global Services (IGS) has been recognized as a major contributor to the successful Ras Tanura Refinery (RTR) 2024 Mega Turnaround and Inspection (T&I) for Saudi Arabian Energy Company (Aramco).

The Environmental Protection Agency (EPA) has been ramping up efforts to enhance air quality nationwide, resulting in stricter emission regulations that pose challenges for Electric Generating Units (EGUs) and non-EGUs alike.

In the ongoing battle to reduce hazardous nitrogen oxide (NOx) emissions, Integrated Global Services (IGS) has provided invaluable assistance to a utility plant, contributing to the nationwide effort to comply with the increasingly stringent emission regulations set forth by the Environmental Protection Agency (EPA).

RAYLEIGH, Essex., April, 2024 - IGS Tube Tech has won an International Safety Award from the British Safety Council in recognition of its commitment to keeping its workers and workplaces healthy and safe during the 2023 calendar year.

Integrated Global Services, Inc. (IGS) has been named a 2023 Supplier Award winner by ADM (NYSE: ADM), a global leader in sustainability sourced solutions from nature.

CFB Boilers by design offer several advantages over conventional boiler designs, including the ability to fire a wide range of fuels and lower combustion temperatures which reduces emissions.

Coal-fired SCR reactors are known to suffer from build-up issues.

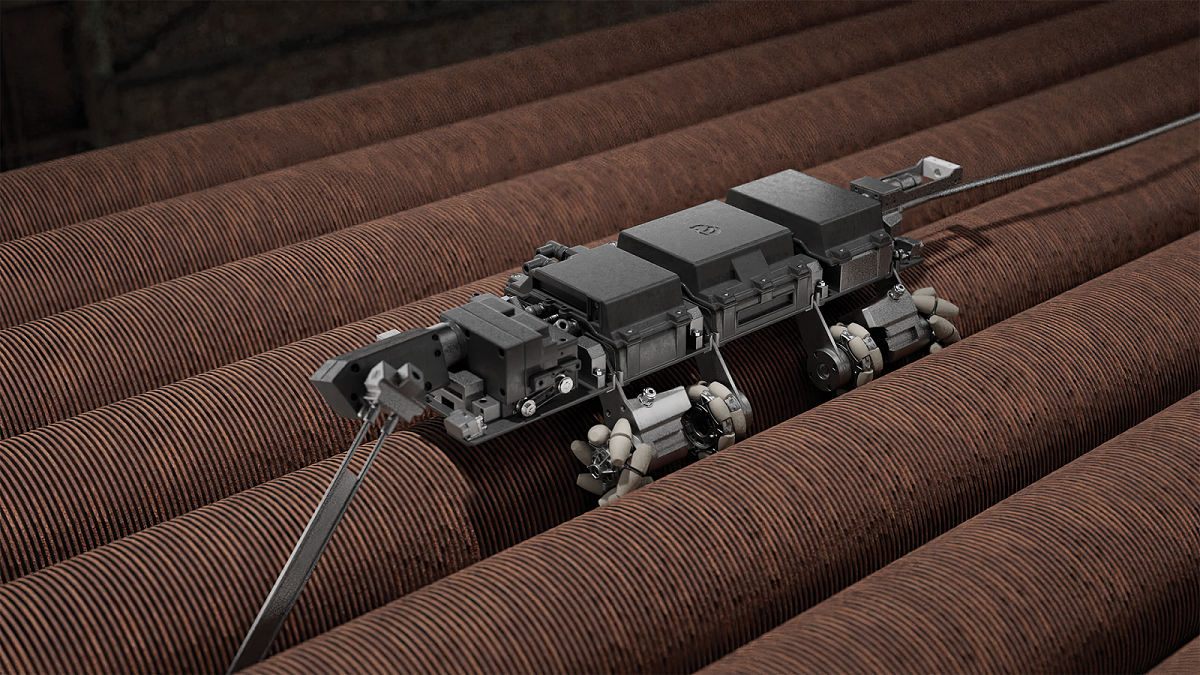

Tube Tech, the leader in premium cleaning and inspection solutions for oil and gas, petrochemical and agrochemical plants, has launched its next generation Mark 7 fired heater rover system capable of remotely eradicating more than 90% of convection section fouling.

In a significant development unveiled at the Trinidad and Tobago Energy Conference, Integrated Global Services (IGS), a global leader in efficiency and reliability solutions, proudly announced its official partnership with Monar Industrial Services.

A waste to energy boiler was experiencing fireside corrosion. Shop applied Alloy 625 weld overlay was showing signs of premature accelerated degradation. IGS was contracted to apply an HVTS cladding on top of the weld overlay in situ to stop corrosion and ensure the reliable and safe operation of the boiler.