Continental Controls Corporation is a leading supplier of fuel control products for both natural gas engines and gas turbine engines. All of CCC’s valves include a CPU integrated into a “smart valve concept”. Mechanically all of the fuel valves provide an exceptionally fast response with minimal friction and hysteresis, and an integrated fuel measurement.

Electronic gas fuel valve

The GV1 gas valve operates as a variable pressure controller monitoring and controlling the gas injection pressure to either the carburetor or mixing venturi of the engine. The valve will respond within 30ms to a change in downstream pressure, which enables the valve to react to load changes much more quickly than a traditional AFR valve that only reacts to changes in the oxygen feedback from the engines exhaust.

The GV1 operates with either naturally aspirated gas engines or (by adding a turbo balance line) with turbocharged engines. The valve can control many types of gaseous fuels such as natural gas, field gas, propane, or various bio-fuels or land fill gasses.

Air fuel ratio control and improved fuel mixing for natural gas engines

By replacing a traditional mechanical Carburetor with a state of the art electronic carburetor the engine can run in either rich or lean burn mode. This can allow for maximum fuel economy while producing the minimum level of unwanted emissions. The Electronic Carburetors are available for engines from 25 hp to approximately 500 hp. In addition to improved engine performance the electronic carburetor will provide reduced maintenance over the traditional carburetor.

By combining a precisely designed mixing venturi and a very fast acting, variable pressure regulator, and integrated control for a wide range oxygen sensor, the EGC 2 and EGC 4 provide the fastest acting and most effective air fuel control and fuel mixing currently available for natural gas, propane, or other alternative gaseous fuel.

Fuel control for ratio control valves and gas turbines

CCC makes a range of fuel control valves for most gas turbines up to about 60,000bhp. These valves all include on board CPUs, with embedded software making them the most sophisticated fuel valves available for turbine engines.

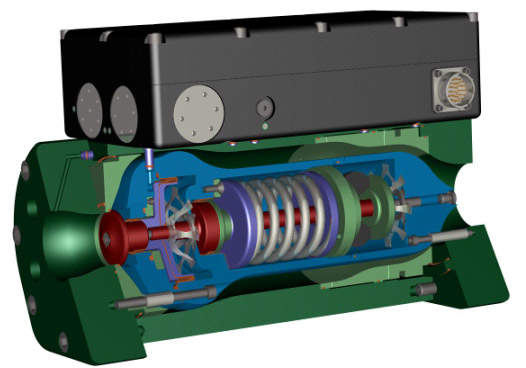

AGV 10/50 gas turbine fuel valve

The AGV 10/50 is a two-stage gas actuated valve that offers exceptional control and diagnostic information for small to mid sized gas turbines. The valve compares the fuel demand signal with a mass flow calculation in the valve to assure the most accurate fuel metering available. The flow measurement signals as well as other diagnostic measurements are available via RS 485 Modbus protocol. Because of the precise fuel flow measurement in the valve, the turbine starts more reliably and runs at a more stable speed than with other fuel valves. The AGV 10/50 is almost impervious to dirt or liquids and can withstand the most demanding environment. These electronic fuel valves require only 24vdc and about 1 amp which allows for much simpler installation and retrofit than some competing actuators.

CCC has fuel valves for the following turbines:

- Solar Turbines- Saturn, Centaur

- Allied Signal – ASE 8, 831, TF 15, TF 25, TF 40, ASE 120

- Dresser Rand – DR-990

- EGT -Hurricane, Typhoon, Tornado

- General Electric-LM 500, LM 1500, LM 1600, LM 2500, Frame 3, Frame 5

- Allison -501 KB, 501 KC,

- Pratt & Whitney-ST6, ST18

- United Technologies-FT4, FT8

- Rolls Royce-Avon

- Kawasaki-M1A, M7A

- Ruston-TA1500, TA1750, TA2500, TB4000, TB5000

Gas turbine diesel fuel valves for the power industry

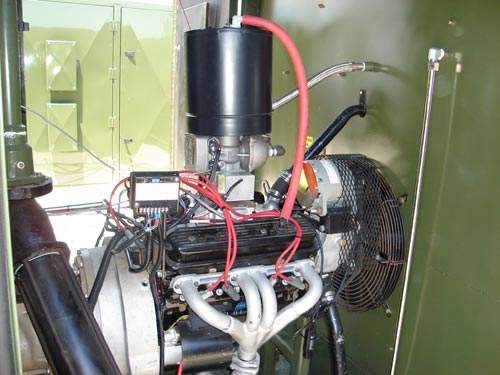

CCC’s Gas Substitution System (GSS) is an advanced technology for allowing diesel engines to also run in bi-fuel mode (30% diesel 70% natural gas).” By using the GSS system operators can run just diesel or they can control the rate of gas substitution for the diesel, up to about 70% natural gas. The GSS is also unique in that it communicates with the diesel engines ECU to determine the maximum safe substitution rate.

By utilising Continental Controls’ proven fuel control technologies, GSS allows for the substitution of gaseous fuels for diesel on traditional diesel engines without any modification to the engine itself. GSS works on all applications from gen-sets to pumps.

It interfaces directly with the engine control unit (ECU) for increased control. Substitution is controlled by using a variable pressure valve which provides more reliable performance and less intervention over long periods of time. GSS substitutes the maximum amount of diesel at almost any load condition for any application. There is no derating of the engine’s horsepower and performance is not affected.

Safety features standard on all systems include: avibration sensor, high temperature shutdown (gaseous fuel substitution only) and max substitution limits basedon measured diesel fuel. The GSS utilises proven technology that has been field-tested with years of successful performance. The GSS features a compact and easy-to-install fuel train with a low profile that fits on almost any engine skid. It is extremely simple to install and operate, with optional satellite and wireless capabilities also available.

Benefits of our GSS include:

- Substitutes low-cost natural gas for diesel

- Variable pressure control valve provides better control

- Substitution is based diesel flow – not load

- Substitution is available at almost all loads

- Shutdowns from vibration or temperature protects the engine from damage

- Fuel valves are voice coil actuated for low friction and long life

- Simple installation

- Various systems for all sizes of diesel engines

- Optional gas flow meter displays totalised fuel savings

- No loss of horsepower with natural gas

Gas turbine natural gas valves

The AGV 50 gas turbine fuel metering valve is intended to meter fuel for turbines in the horsepower range of approximately 5,000HP to 60,000HP. This intelligent fuel valve includes a built in venturi based flow meter providing a very accurate calculation of fuel flow.

By providing an internal mass flow calculation, the valve is able to insure accurate fuel flow even with changes in supply or back pressure or changes in ambient air temperature.

Its high turn down ratio accommodates a wide range of gas turbines, with a robust and dirt-tolerant design.

Fuel flow measurement

Various agencies now require fuel measurement on individual turbines and gas engines. The FM-50 offers a simple-to-install option that can provide instantaneous flow or totalised flow over a period of hours, days or months. It provides a true mass flow calculation which corrects for temperature or pressure fluctuations.

The meter is calibrated at the factory and automatically corrects for pressure sensor drift each time the meter is powered down.

The Venturi used for flow measurement has been carefully designed to minimise the pressure drop across the device.