Joining Technologies was founded in 1992 and is a company built on innovation. Our top-notch expertise, exclusive technologies and high performance culture have developed joining solutions once thought to be impossible.

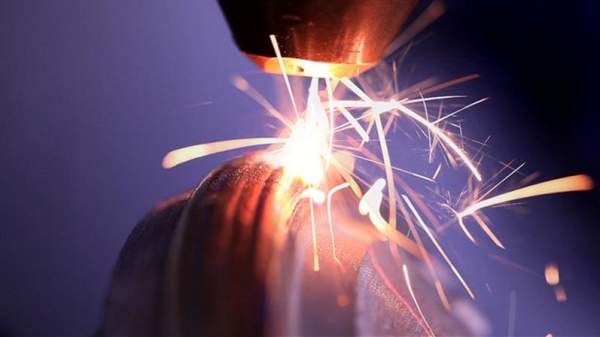

Laser cladding of metal powder alloys

Joining Technologies additive uses laser cladding of metal powder alloys to enhance, repair or free-form material for applications in power generation, oil and gas exploration, industrial heavy equipment, petrochemical and aerospace.

Our new laser additive facility in East Granby, Connecticut, US, enables us to find solutions for components up to 40ft in length and 7 tons in weight. Some items JTAD currently specializes in include industrial gas turbine (IGT) component repair, boiler / super heater overlays and valve hard facings.

Laser additive manufacturing services

The unprecedented precision and reliability of our laser cladding processes is now available to private industry. As a leading provider of LAM (laser additive manufacturing) surface restoration technology, we are able to create true metallurgical bonds between virtually unlimited metal types. Precisely focused lasers enable us to create an extraordinarily small heat affected zone (HAZ) and dilution area for superior strength, hardness, and performance properties.

Laser cladding processes

Joining Technologies uses laser cladding of metal powder alloys to enhance, repair or free-form material for applications in aerospace, power-generation, valve and OEM-supplied components. Our laser additive processes offer positional accuracy, while maintaining material quality and metallurgical bonding.

Advantages of laser additive manufacturing

The laser additive manufacturing process is used to laser clad metal powder alloys when enhancing or repairing parts. Using a laser to create a melt-pool on the work piece, powdered metal is fed through a nozzle into the weld puddle, creating a clad layer. Unlike high velocity oxygen fuel (HVOF), the LAM process achieves a full metallurgical bond by fully melting the surface of the substrate while applying powder.

The precisely targeted heat of the laser allows for lower penetrations of the parent material, resulting in a smaller HAZ and a lower dilution area. This translates to an enhanced grain structure and lower minimum clad thickness required to achieve desired hardness, as compared to PTA applied clads. Parametric accuracy of the system allows for clad layers as thin as 0.004in, with the maximum clad thicknesses ranging over 3in.