nHance Technologies is announcing the delivery of an engineering process and control simulation of a gas compressor refilling station for the purpose of system design optimisation and control logic evaluation.

nHance Technologies is announcing the delivery of an engineering process and control simulation of a gas compressor refilling station for the purpose of system design optimisation and control logic evaluation.

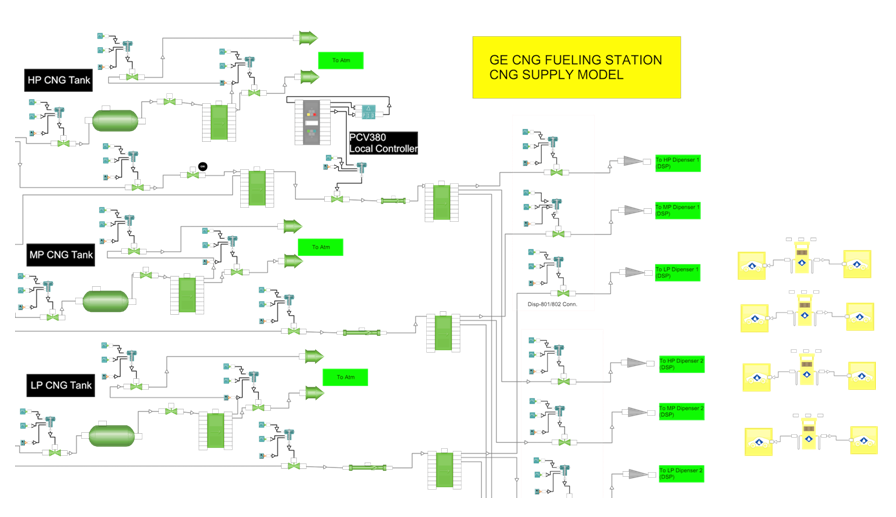

The compressor driven refilling station provides a compact solution for fueling of natural gas vehicles. A typical station consists of a natural gas source, a reciprocal compressor, intercoolers, buffer storage tanks and CNG dispensers. The MMS process model was developed to carefully model the system components in an attempt to match the existing behavior and plant output data.

The process of filling vehicles at a CNG station is a dynamic process that requires the cyclical filling and emptying of the buffer storage tanks, as well as a series of compressor starts and stops. Gas is removed from high, medium and low pressure buffer tanks via the dispensers to provide the fastest fill for the customer. The MMS model was designed to test optimization of fill times, and control set points to deliver the quickest service under a variety of filling scenarios. In addition, the MMS model was used to verify and develop control coding for the existing and newly designed plant models.

Many new modules were added to the MMS library of components to model this process. Natural gas property routines were created to complement the extensive MMS water property library of routines. The new routines were implemented with the flexibility to easily add other property routines outside of natural gas for modeling multiple compressed gas systems.

To provide control code emulation that is both accurate and quick to turnaround, two control translators were developed to convert actual control coding output into native MMS format. Control translators were developed for both Allen Bradley (AB) and General Electric ProficyTM Machine Edition (PME). Use of the AB and PME translators allowed for engineers to incorporate their control changes into the model with a minimum of time and effort allowing for more time to test and execute the simulation. In addition, an AB to PME translator was developed to save time and expense in developing initial control logic for the PME platform on the real system.

The flexibility and modular design of the MMS tools allow for changes in the plant design to be quickly realised in the simulation. Control translation allows for the model to have the latest control coding quickly and efficiently. The entire engineering process simulation package is but one example of how nHance Technologies strives to develop cost effective, unique solutions to our customer’s unique problems.

nHance Technologies has offered cost-effective solutions with successful results for over 30 years. nHance is not only a vendor, but also ‘your partner in simulation’.